Concentrol is a leading company in the chemical solutions sector. As a result of its process of expansion and consolidation in the international market, the company has noted a substantial increase in demands from customers seeking customized solutions for their industrial processes.

This increase in the demands has meant making a series of internal changes in order to take advantage of time, space, and productivity and, in this way, achieve more effective work, providing professional and quality coverage of the current market’s demands.

One of the most important changes carried out internally has been the implementation of the 5S, a work methodology with the objective of obtaining clean and organized work areas, improving productivity and safety, and optimizing working time. This innovative methodology is divided into:

- 1S: Seiri. Classify work items according to their usefulness.

- 2S: Seiton. Arrange the elements in strategic places.

- 3S: Six. Clean the accumulated dirt and carry out maintenance of the machinery.

- 4S: Seiketsu. Standardization of the previous three steps, and execute them every day.

- 5S: Shitsuke. Discipline, through audits to check if the previous 4S are applied.

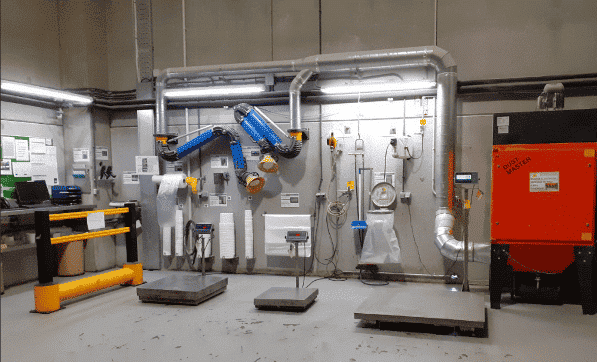

The 5S methodology has been applied, specifically, in the weighing area. Following the protocol established by this method, in the 1S the material has been classified and the elements have been separated to clear the area as much as possible, deciding each utensil’s strategic places. In the 2S, all the material in each area has been classified and strategically placed for a more agile use. For the 3S, the area has been cleaned and the sources of dirt have been checked. The floor has been painted to make dirt more visible. In the 4S, standardization, information sheets have been created to know when to clean each element and where exactly they are stored. Finally, in the 5S there has been an audit to ensure discipline and correct monitoring of the cleaning plan.

The application of this new method can be added to the rest of the internal organization changes that Concentrol has already put into practice to make work more effective. The ultimate goal is to ensure the safety and well-being of all workers and, at the same time, to be a benchmark in matters of work efficiency.