Concentrol is a leading company in the chemical solutions sector that works by structuring its product lines in four divisions: Performance Materials, Food Processing Aids, Additives and Adhesives. Footwear is one of the sectors with the most product lines by Concentrol for the manufacturing process of monodensity and bidensity soles and shoes. In addition, we have products for the different manufacturing processes: direct injection or subsequent assembly.

Silicone surfactants are copolymers made up of a silicone base and polyethers and polyethylene and polypropylene oxide chains. The different types of compositions that can be made combining all these elements will lead to differences in the function of the final surfactant.

Polyurethane foams designed exclusively for footwear or integral polyurethane foam have a very similar composition, which is why there are surfactants that can work with both systems equally. However, it should also be borne in mind that there are different types of surfactants: those that are designed for polyester-based PU systems (in integral PU and footwear) and those that are for polyester-based systems (only in PU for footwear). Additionally, there are silicone stabilizers that can also be used in combination with other surfactants, so they act as co-surfactants, offering improvements to the surface appearance and cell structure of the foam.

This type of PU foam, with very similar characteristics to rubber, usually has elastic properties and abrasion resistance. In the case of shoe soles, the use of this foam is very suitable, as it provides a point of resistance to the wear and tear of everyday use.

When evaluating polyurethane foam, once the system has been formulated with the appropriate surfactants, four factors must be taken into account that are key to determining its quality:

- Its Ross-Flex properties, i.e. resistance to flexibility. A machine calculates the ability of the material to withstand cracking due to continuous and rapid bending. In tests of this parameter, a device is used that makes the same movement about 100 times repeatedly.

In this image you can see the technical device used to analyze the Ross-Flex properties at the beginning of the test and in the bending phase of the studied material.

- Degree of hardness. The natural hardness of materials is usually calculated with devices called durometers, in which a series of plastics and rubbers are used. However, it is not possible to establish a simple relationship between the hardness of the material and its fundamental property.

- Tensile strength, i.e. the natural resistance of a plastic material to breaking due to an elongation force. This parameter is usually measured with a dynamometer, and the exercise consists of cutting a piece of material in the shape of a loop and calculating how much force it needs to break.

The device used to measure the tensile strength of a material, in a test.

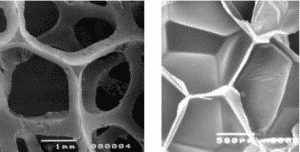

- Cell regulation. It is important to analyse in detail the components of the material to try to find a cell structure as small and uniform as possible, also minimizing surface defects such as “pinholes”, i.e. those small craters that may appear on the surface of the products and which compromise their strength and tightness. Finally, it should also be noted that it is preferable to look for a cell opening that is completely or partially open, since a closed cell structure leads to shrinkage defects.

The first image shows the detailed composition of an open cell. The second shows a closed cell.

These aspects of the foam can be regulated with the use of surfactants, as they are additives that allow the formulation of thin, thick, closed and open cells, and these cellular structures influence the final properties of integral PU foam and for footwear.

Concentrol is a diversified company that works to bring its chemical solutions to all sectors, and researches to make them as sustainable as possible. End customers are one of the most important parts for Concentrol, which is why we always try to find the best possible service and product customization.

Author: Josep Nadal – Technical Manager