In Concentrol’s Additives division we respond to all the needs of very diverse industrial sectors. We manufacture products adjusted for each client because we have extensive knowledge in the sector.

Below we present a comparative study carried out on the effectiveness of antifoams in aqueous dispersion of acrylic styrene with EMULTROL DFM AFO-1, EMULTROL DFM AFO-10 and a market reference.

To determine the short-term and long-term antifoam efficacy of the different antifoam agents compared in the present study, microfoam tests based on the agitation method have been performed. Using an aqueous dispersion based on styrene acrylic copolymers as the medium.

The compared references are composed of aqueous emulsions of mineral oils with different concentrations of solids.

| Antifoaming agent | Type | Solid content (%) |

| Market reference | Mineral oils in aqueous emulsion | 70 |

| EMULTROL DFM AFO-10 | Mineral oils in aqueous emulsion | 22 |

| EMULTROL DFM AFO-1 | Mineral oils in aqueous emulsion | 55 |

Table 1. The trade name, composition and solids content of the different antifoaming agents used in the present study.

METHODOLOGY

200 g of aqueous styrene acrylic dispersion are weighed into a 1000 mL container and a dose of 0.2-0.4% of antifoam agent is added. The preparation is vigorously stirred with a mechanical shaker at 1300 rpm, for 5 minutes. The density of the preparation is then measured to determine the density of entrained air. The preparation is aged in an oven at 45 °C for one week and the test is repeated to determine the stability of the antifoam effect after the aging of the dispersion.

RESULTS

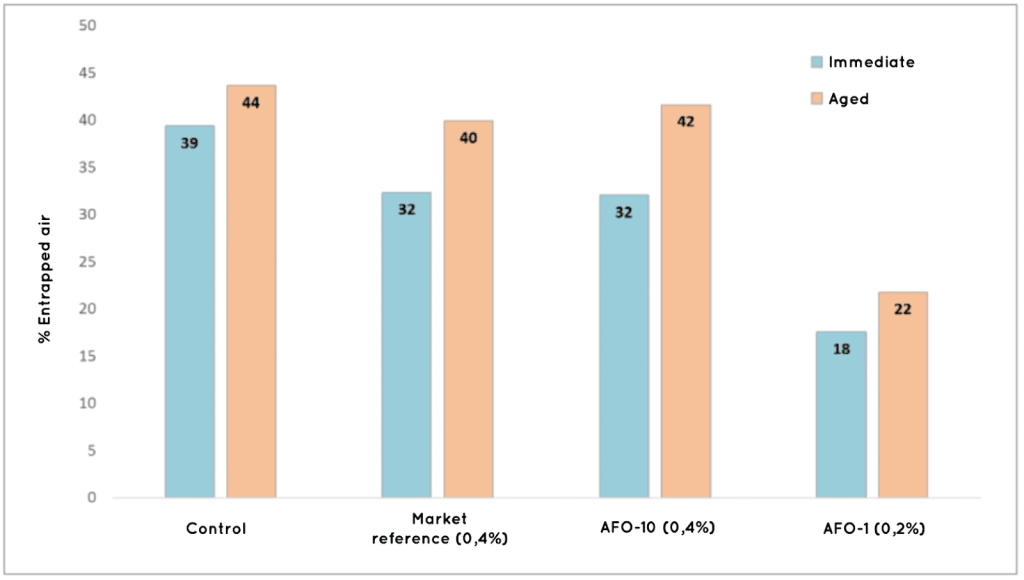

| Antifoaming agent | Dose % | Entrapped air % (immediate) | Entrapped air % (aged) |

| Control | – | 39 | 44 |

| Market reference | 0.4 | 32 | 40 |

| EMULTROL DFM AFO-10 | 0.4 | 32 | 42 |

| EMULTROL DFM AFO-1 | 0.2 | 18 | 22 |

Table 2. Shows the% of entrapped air, calculated from the density resulting from the microfoam tests, of the different antifoam agents compared, together with their respective added dose.

Graph 1. The graph shows the % of entrapped air of the different antifoam agents, together with their respective dose, the results of the immediate test and the aging test are shown.

CONCLUSION

The reference antifoam on the market and the product Concentrol EMULTROL DFM AFO-10 show a similar antifoam capacity, while the EMULTROL DFM AFO-1 line shows superior antifoaming effectiveness even at half the dosage, with respect to the other references compared in the present study.

Concentrol studies the particular case of each client and conducts studies to provide the most appropriate solution for their requirements. With full control of the manufacturing process, Concentrol designs product lines with different properties and levels of compatibility so that the customer has the best solution at their disposal according to their needs. Contact us for more information.

Author: Lorenzo Rico

Technical Manager