Foam is a stable dispersion of air in a liquid medium stabilized by a surfactant or compound with surfactant properties. In the case of coatings, air can be incorporated in the mixing process during the grinding phase between the plastic polymer and the inorganic fillers and pigments, in the discharge phase, in packaging processes by pumping systems or due to agitation or pressure changes in the final stages of roller, brush or spray painting.

Controlling the formation of foam in the coatings sector has always been a challenge, since the antifoaming agent must be effective during the manufacturing process and while offering excellent efficiency during the life of the coating, which in many cases it is long. In addition, coating formulations must currently comply with strict environmental regulations that limit, for example, the amount of volatile compounds (VOC and SVOC) that can take part in atmospheric photochemical processes and are considered to favour the formation of ozone at the surface level1.

Traditionally, antifoaming agents used to control foaming in these applications are based on mineral oils whose origin is petroleum. These antifoaming agents are economical and effective, but they are virtually toxic (to a greater or lesser extent depending on the type and origin of the mineral oil used) and in many cases they contain high amounts of VOC and SVOC. Recently, the European Commission and countries such as Germany have started risk assessment processes associated with these materials2 3, generating the need to declare the presence of mineral oils and aromatic mineral oils (MOSH and MOAH) in many food products. For this reason, the replacement of these mineral oils with alternatives of lower toxicity, lower emissions, of a non-petroleum origin and environmentally more favourable is an increasingly important requirement.

According to recent data provided by the EU, currently four out of every five European consumers wish to buy more environmentally friendly products. Without any doubt, consumers today are more aware than ever that environmental protection is essential.

An excellent source of biodegradable hydrophobic oils is found in esters of plant origin, which are obtained by the trans-esterification reaction of vegetable triglycerides (vegetable oils) with different alcohols. In this study, these raw materials of sustainable origin have been assessed in the formulation of antifoaming agents that are free of volatile compounds (VOC), biodegradable and non-toxic for coatings and paints with minimum emissions or emission-free.

Of the total coatings market, more than 50% are considered architectural paintings. Paints for walls, both interior and exterior, ceilings and facades represent the largest volume of this type of paints and, although cost is always one of the most important factors, the industry’s willingness to offer clean labelling and to meet strict requirements, such as the Ecolabel, gains more and more importance and interest. According to decision 2014/312/EU, May 28, 20144, any ingredient / substance / preparation / mixture intentionally added to the raw material must be declared. This includes impurities and by-products that are present in concentrations greater than 0.010% in the raw material.

NEW SOLUTIONS FOR FOAM CONTROL IN PAINTINGS

We present the new antifoaming agent EMULTROL DFM OLV-24, the first one of a new range of products, designed following the criteria of biodegradability, low or no toxicity and low or zero emissions of volatile components (VOC and SVOC). It is based on vegetable esters that are obtained sustainably and totally free of traditional mineral oils. Even with these changes, the careful formulation and selection of raw materials has enabled us to obtain an antifoaming agent that offers a performance equal to or in some cases superior to that obtained with traditional antifoaming agents based on mineral oils.

For the assessment of the antifoaming effectiveness of this new product, tests of effectiveness, stability and compatibility have been designed at Concentrol’s application laboratories, using in this case the most common polymer dispersions in the manufacture of architectural paints: acrylic polymer, polymer styrene-acrylic and vinyl-veova polymer.

DISCUSSION OF RESULTS

Materials

| Type | Manufacturer | Solids (%) | MFFT (ºC) | pH |

| Styrene-acrylic polymer 1 | BASF | 50 | 22 | 6.5-8.5 |

| Styrene-acrylic polymer 2 | Hexion | 50 | 16 | 8 |

| Vinyl-veova polymer | Resiquímica | 55 | 15 | 4-5 |

| Acrylic polymer 2 | BASF | 48 | 14 | 7.5-8.5 |

| Acrylic polymer 3 | BASF | 45 | < 3 | 7.5-8.5 |

| Acrylic polymer 1 | Hexion | 48 | 25 | 6.5-8.5 |

Antifoaming effectiveness

To evaluate the effectiveness, a 200ml sample of the polymer dispersion in a beaker is taken, 0.2% of the antifoaming agent to be tested is added and a stirring process is started at 1300 rpm for 5 minutes. The percentage of occluded air is calculated by measuring the density and the relationship between this value and the initial density (pycnometer 100ml).

Persistence of the antifoaming effect

Another parameter to consider is the effectiveness of the antifoaming agent in the long term, once formulated in the paint. It is very important that it shows high effectiveness over time to ensure that the paint has optimal properties during its shelf life. That is why tests have been developed that simulate accelerated aging, in this case with a test at 45 °C for one week, in the dosage of 0.2% antifoaming agent in the paint. Next, the effectiveness test described above is reproduced.

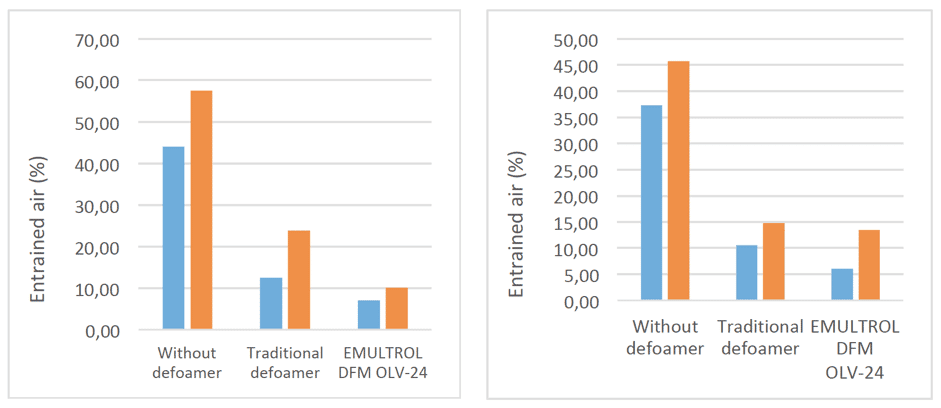

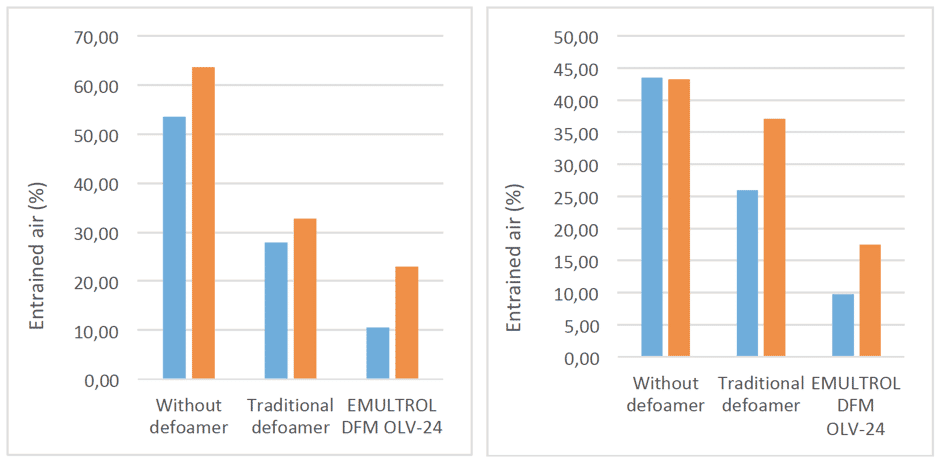

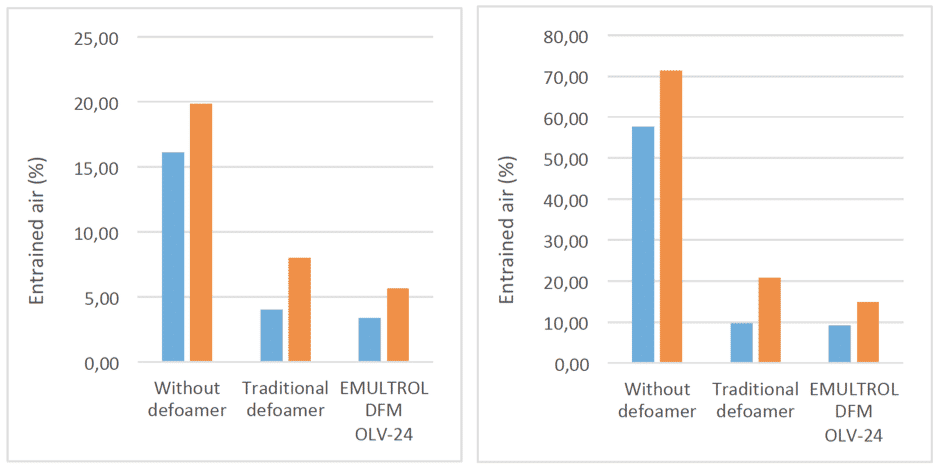

Figure 1 shows the results of the effectiveness and persistence of the antifoaming effect of the new EMULTROL DFM OLV-24 antifoaming agent in each of the polymers studied. In all of them, a comparison has been made with a reference antifoaming agent for architectural paints, based on a dispersion of hydrophobic components in a mineral oil.

Figure 1. Results of the antifoaming test with EMULTROL DFM OLV-24 in a comparative test with a traditional mineral oil based antifoam.

a) Acrylic polymer 1 b) Acrylic polymer 12

a ) Acrylic polymer 3 b) Styrene-acrylic polymer 1

a)Styrene-acrylic polymer 2 b)Vinyl-veova polymer

Blue: Fresh test Orange: Aged test (1 week at 45 ºC)

We can highlight that in all the polymers evaluated the effectiveness of the new antifoaming agent is good, and it also has a very effective aging test result. In some cases the effectiveness virtually does not change over time, thus guaranteeing an effect both at the time of paint manufacturing and at its final application.

Also note that the tests show that in most polymers the effectiveness of the new EMULTROL DFM OLV-24 antifoaming agent is superior to that achieved with the mineral oil-based equivalent.

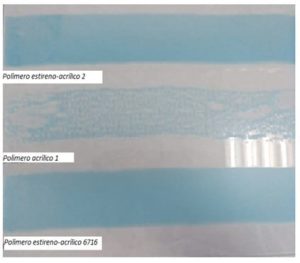

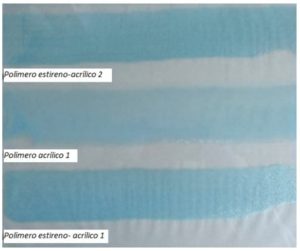

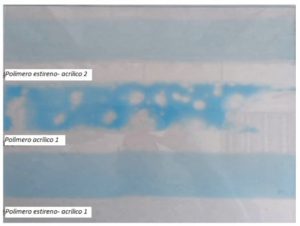

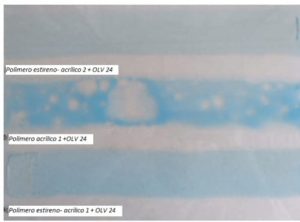

Antifoaming agent Compatibility

Finally, the compatibility of the different antifoaming agent with the different polymer dispersions is assessed, in order to verify that in addition to a good initial and aged effectiveness, the antifoaming agent does not cause wetting problems such as fish eyes, craters or orange peel that would result in poor application of the paint. To that end, an application of a thin layer of 120 microns on glass support has been tested. The compatibility results of the new EMULTROL DFM OLV-24 antifoaming agent in 3 of the polymers studied are detailed in Figure 2.

Figure 2. Wetting test of EMULTROL DFM OLV-24 antifoaming agent in 3 polymers.

120 microns, without antifoaming agent, stirred and 120 microns, without antifoaming agent, 24h

The 3 polymers have a good wetting in extension without stirring. Once stirred (1300rpm, 5min), foam formation is observed in all three. Very evident in the case of acrylic polymer 3.

120 microns, 0.2% DFM OLV-24, stirred and 120 microns, 0.2% DFM OLV-24, 24h

The addition of the antifoaming agent causes incompatibility in acrylic polymer 3 and good compatibility in the other 2. This effect remains 24 hours after the test.

This result shows that it is always necessary to evaluate not only the antifoaming effectiveness, but also its persistence and compatibility, since incompatibilities may arise in certain formulations. This result is in accordance and to some extent expected, if we consider that the antifoaming agent EMULTROL DFM OLV-24 is formulated with highly hydrophobic components and is considered an apolar antifoaming agent, recommended in initial dosages (grinding) and in high PVC paints.

In any case, no significant difference has been observed compared to the results obtained using an antifoaming agent based on usual mineral oils.

CONCLUSIONS

Antifoaming agents can be formulated free of mineral oils, with the advantages that this entails, demonstrating in addition an excellent antifoaming efficiency, a good persistence of the effect on the paint and without any compatibility problems in the final application of the paint other than those produced with usual hydrophobic antifoaming agents.

These results are valid for different polymers common in the field of architectural paints, specifically those that use acrylic, styrene-acrylic and vinyl-acrylic dispersions.

It is possible to substitute antifoaming agents based on mineral oils with new alternatives based on oils of vegetable origin, which makes it possible to take a very important step forward to obtain paints with lower emissions, without hydrocarbons, with biodegradable additives and with an excellent result of application.

In the previous article, we saw how to obtain the Ecolabel certification in the paints sector, in this new instalment they have been compared to traditional oil-based antifoaming agents.

At Concentrol we work every day to improve our chemical solutions, adapting to market trends and environmentally good products for the planet. With these two premises, we innovate and improve to offer the best service to customers.

References

¹ https://www.epa.gov/ground-level-ozone-pollution/ground-level-ozone-basics

2 Commission Recommendation (EU) 2017/84 of January 16, 2017 on the monitoring of hydrocarbons of mineral oils in food and in materials and objects intended to come into contact with food

3 https://www.bfr.bund.de/en/questions_and_answers_on_mineral_oil_components_in_food-132254.html

4 COMMISSION DECISION of May 28, 2014 establishing the ecological criteria for the granting of the EU Ecolabel to interior and exterior paints and varnishes