Concentrol has carried out an evaluation study of adhesive values. The formulations have been made with different types of resin dispersions from the EMULTROL range, together with an acrylic dispersion of the Acronal type.

The conclusions of this study allow us to verify the properties of each of the proportions, and for each of the products evaluated. Knowing the response of our chemical solutions in different scenarios is essential for customers to find the right product for each application.

To carry out the study, two combinations of acrylic dispersion with resin dispersion have been used in two different proportions:

– 70% acrylic dispersion + 30% resin dispersion

– 80% acrylic dispersion + 20% resin dispersion

The products used are:

– Emultrol E-55 (hydrogenated HC hybrid dispersion with rosin ester)

– Emultrol E-175 A (hydrogenated HC hybrid dispersion with rosin ester)

– Emultrol E-77 H (esterified rosin)

– Emultrol E-60 (terpene phenolic resin)

– Emultrol E-600TH (terpene phenolic hybrid dispersion with rosin ester)

– Emultrol E-500 AH (aliphatic HC hybrid dispersion with rosin ester)

The acrylic dispersion responds to an Acronal V-215.

EMULTROL solutions

The six tested resin dispersions correspond to the EMULTROL range. The main mission of these solutions is to improve the cohesion, tack and adhesion properties of self-adhesives based on polymer dispersions of acrylic resin, PVA, EVA, SBR, NBR, natural latex, polychloroprene and aqueous polyurethane dispersions.

They increase adhesion and tack on non-polar substrates and low energy surfaces, improving their wetting capacity. We have a wide range of microemulsions with different characteristics, origins and types of resins depending on their application: acid and esterified rosin resins, hydrocarbon resins, terpenephenolic resins, hybrids, etc. Our dispersions are highly stabilized against oxidation and the action of ultraviolet rays.

Adhesive value results

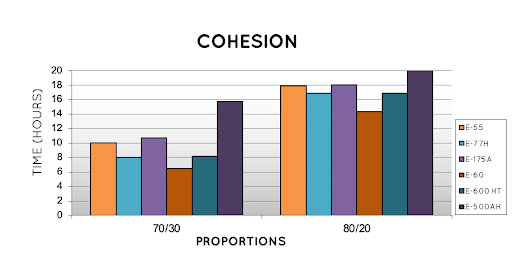

Cohesion

Hybrid resins are those with the best cohesion properties. It is observed in the 70:30 ratio where the effect of the resin is more important.

| Acril/Resin | E-55 | E-77H | E-175A | E-60 | E-600TH | E-500AH |

| 70/30 | 10,01 | 8,01 | 10,71 | 6,48 | 8,20 | 15,72 |

| 80/20 | 17,92 | 16,92 | 18,05 | 14,33 | 16,94 | 23,20 |

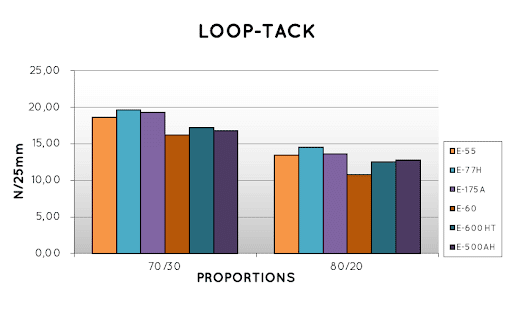

Steel loop tack

Good tack properties of the rosin ester with a high yield of hybrids with values very similar to E-77 H

| Acril/Resin | E-55 | E-77H | E-175A | E-60 | E-600TH | E-500AH |

| 70/30 | 18,6 | 19,64 | 19,33 | 16,22 | 17,2 | 16,8 |

| 80/20 | 13,49 | 14,50 | 13,61 | 10,75 | 12,52 | 12,8 |

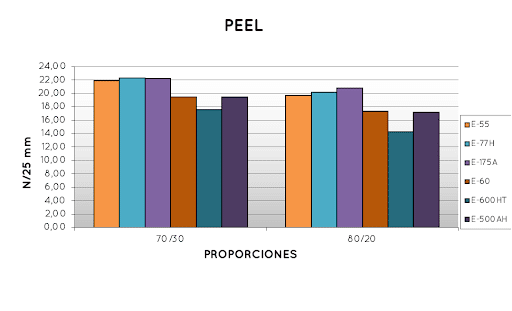

Steel peel

Practically similar values of adhesion of the hybrid dispersions E-55 and E-175 A compared to E-77 H.

| Acril/Resin | E-55 | E-77H | E-175A | E-60 | E-600TH | E-500AH |

| 70/30 | 21,9 | 22,3 | 22,21 | 19,48 | 17,55 | 19,45 |

| 80/20 | 19,66 | 20,2 | 20,77 | 17,3 | 14,25 | 17,17 |

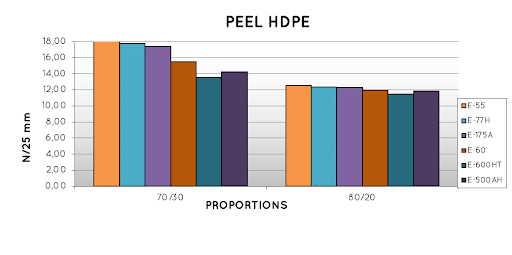

Peel HDPE

A better performance of E-55 is observed on plastic surfaces with values similar to that of E-175 A and E-77 H. At 80:20 ratios, this difference between the resin dispersions is not detected due to the effect of the acrylic.

| Acril/Resin | E-55 | E-77 H | E-175A | E-60 | E-600TH | E-500AH |

| 70/30 | 9 | 7,56 | 7,81 | 12,3 | 12,4 | 9,3 |

| 80/20 | 7,3 | 6,4 | 6,23 | 9,5 | 8,42 | 6,78 |

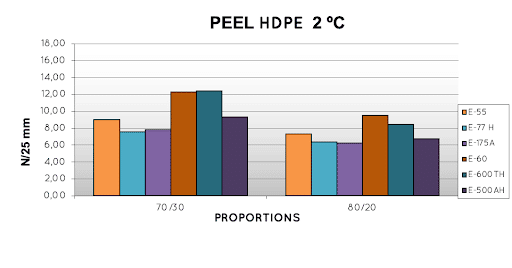

Peel HDPE 2ºC

Higher yield of terpene phenolics and hybrid E-55, E-500 AH and E-600 TH compared to rosins.

| Acril/Resin | E-55 | E-77 H | E-175A | E-60 | E-600TH | E-500AH |

| 70/30 | 9 | 7,56 | 7,81 | 12,3 | 12,4 | 9,3 |

| 80/20 | 7,3 | 6,4 | 6,23 | 9,5 | 8,42 | 6,78 |

The chemical company has carried out other complementary tests that will be presented in future publications. A team of technicians works every day in our laboratories to develop products that meet the needs of our customers around the world.