From the Performance Materials, Food Processing Aids, Additives and Adhesives divisions, Concentrol responds to the needs of its customers. Each of our products is designed and produced by expert technicians and professionals in the sector. One of the essential phases in our solution creation processes is precisely carrying out studies to verify the efficacy and safety of the product.

This article contains two studies carried out in Concentrol laboratories in order to evaluate the use of ORDISOL SWT-27 and ORDISOL SWT-45 for water-based industrial paints.

STUDY 1. Comparative study of humectant in aqueous dispersion with ORDISOL SWT-27 AND ORDISOL SWT-45.

En el presente estudio se compara la efectividad para reducir los defectos superficiales, tales como pliegues y cráteres. En un recubrimiento aplicado a pistola, sobre metal, se comparan los efectos en el acabado del recubrimiento con ORDISOL SWT-27 y con ORDISOL SWT-45.

The present study compares the effectiveness to reduce surface defects, such as folds and craters. In a spray-applied coating on metal, the effects on the finish of the coating with ORDISOL SWT-27 and ORDISOL SWT-45 are compared.

Methodology

We use a water-based paint medium. We dilute it with 5% water, homogenize it and apply it with a spray gun on an enameled contrast card at a temperature of 25 °C. The pressure, fan opening and trigger settings are (2: 3: 3) respectively.

Once the first coat of paint has been applied, vertically, we let it dry for 5 minutes at room temperature and then for 8 minutes at 180 °C. We apply the second coat and repeat the previous drying procedure. Finally, we measure the g / m2 of the applied coating, by gravimetry, and we make a visual comparison of the wetting and the count of craters and surface defects visible to the naked eye.

| Test | Dosage (%) | Craters | Layer thickness (g/m2) |

| Control | – | > 100 | 23 |

| ORDISOL SWT-27 | 0,4 | 18 | 35 |

| ORDISOL SWT-45 | 0,4 | 15 | 36 |

| ORDISOL SWT-27

+ ORDISOL SWT-45 |

0.2% + 0,2% | 12 | 32 |

Comparative table of surface defects, such as folds, craters and the thickness of the layer analyzed, of the applications of the coating made with the different wetting agents studied.

There is a big difference in the amount of paint applied to the Control application, since it has a much lower layer thickness than the rest of the tests. This action reduces the appearance of craters in the Control test.

In the tests with ORDISOL SWT we observed a great reduction of craters compared to the Control test.

Study 1 conclusions

After carrying out the study, we recommend the combination of the additives ORDISOL SWT-27 AND ORDISOL SWT-45 with a dose of 0.2% of each, in water-based paint, since it significantly reduces the amount of surface defects.

STUDY 2. Comparative study of water-based coatings applied by spray with surface additives ORDISOL SWT-45 and ORDISOL SWT-27

In this study we compare surface defects such as crater formation, pinholes and vertical run-off in water-based enamel-type coatings with ORDISOL SWT-45 and ORDISOL SWT-27 surface additives.

In order to find a combination of surface additives that provide good wetting and levelling of the coating, resulting in a finish with a minimum presence of surface defects, a series of applications of the enamel paint have been carried out using an airbrush spray with the different surface additives to compare.

The applications have been made in all cases by the same technician, under the same conditions of air pressure, flow, opening and distance of application. 100x190mm white contrast cards have been used as support.

The results have been observed after 48 hours of drying for the water-based enamel paints, then they have been analyzed in search of craters, micro-craters, pinhole count and drainage, both with the naked eye and with an electron microscope (x60).

We have designed a series of experiments (Table 1). In each one of them, the enamel paint is mixed together with the catalyst (2:1) and osmotic water to obtain a viscosity of 18 ”F4. In the case of enamel paints without additives, different surface additives have been added in order to compare their surface effects after drying.

| H1 | Water-based enamel paint without additives |

| H2 | Water-based enamel paint with additives on the market |

| H3 | Water-based enamel paint without additives + 0,4% ORDISOL SWT-27 |

| H4 | Water-based enamel paint without additives + 0,4% ORDISOL SWT-45 |

| H5 | Water-based enamel paint without additives + 0,2% ORDISOL SWT-45 + 0,2% ORDISOL SWT-45 |

Table 1. This table shows the series of tests carried out.

H1-H5 Water-based enamel paint tests

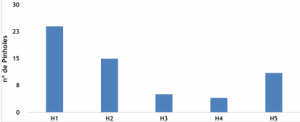

In the series of tests with water-based enamel paint we can observe with the help of the microscope the presence of micro-craters of about 100-10 µm (Graph 1). Also, drops and runoff are observed due to the vertical inclination of the application. These defects are common in all water-based enamel paint tests and could be due to a low viscosity of the preparation.

Where we have been able to observe differences is in the amount of pinholes of the different combinations of additives. To make the comparison, we have counted the pinholes along the last 3 cm of the painted surface (graph 1). It can be seen that the enamel test without additives is the one that shows the most pinholes by far, while the tests with ORDISOL SWT-27 and ORDISOL SWT-45 additives (H3 and H4) show three times less pinholes than the enamel paint with standard additives .

Water-based enamel paint

Graph 1. This graph facilitates the comparison between the number of pinholes observed within the lower 3 cm of the painted surface.

Study 2 conclusions

Regarding water-based enamel paint, no reportable crater differences are seen. On the other hand, regarding pinholes, it can be seen that both enamel paint with the surface additives ORDISOL SWT-27 and ORDISOL SWT-45 considerably reduce the presence of pinholes compared to standard enamel paint, being ORDISOL SWT-45 at 0.4% the one that shows the best results.

At Concentrol we are committed day after day to research and knowledge as a key formula to present the best value solutions to our clients. We are currently present in 5 continents and 82 countries, where we find world powers in the sector such as China, India, Vietnam, Indonesia, Brazil, Turkey, Pakistan, Mexico, Italy, the United States, Thailand, Russia, the United Kingdom, the Netherlands, Belgium, Morocco, Spain and Portugal, among others.