Commitment to knowledge and research is in Concentrol’s DNA. From our four divisions, Performance Materials, Food Processing Aids, Additives and Adhesives, we present the best solutions after a rigorous process of development and verification of the effectiveness and quality of each of the products.

This study compares the antifoaming capacity and the deaeration capacity of some antifoaming products on the market with our solutions EMULTROL DFM AFO-5, EMULTROL DFM OLV-24, EMULTROL DFM AFO-24 and EMULTROL DFM AFO-1.

To evaluate and compare the short and long-term performance of the different antifoaming agents, a stirring method has been carried out, directly after the addition of the antifoaming agent and also after an aging process.

The different antifoaming agents, their composition and their solid content are shown in Table 1. This information has been used to adjust the dosage of the antifoaming agent in the tests in order to always compare the antifoaming agents with the same solid content.

Table 1. The commercial name, chemical grade or class and the solid content of the different antifoaming agents used in this study are shown.

| Antifoaming agent | Type | Solid content (%) |

| Product 1 | Mineral oil emulsion | 28 |

| Product 2 | Vegetable oil emulsion | 30 |

| Product 3 | Vegetable oil | 100 |

| EMULTROL DFM AFO-1 | Mineral oil emulsion | 50 |

| EMULTROL DFM AFO-5 | Vegetable oil emulsion | 22 |

| EMULTROL DFM OLV-24 | Esterified vegetable oil | 100 |

| EMULTROL DFM AFO-24 | Esterified vegetable oil emulsion | 50 |

Methodology

The entire test was carried out on a styrene-acrylic copolymer dispersion. To perform the antifoaming tests, 200 mL of the acrylic styrene dispersion were measured with a dose of 0.2-0.45% of the antifoaming agent, depending on the solid content of the antifoam, except vacuum.

The mixtures have been stirred at 1300 rpm for 5 minutes. Finally, the density of the sample has been measured to determine the percentage of occluded air. Subsequently, the same antifoaming test was repeated with a sample aged by preserving at 45 °C for 7 days.

Results

Table 2. The different doses, the results of both fresh and aged antifoaming tests incorporated into the air are shown. As can be seen, the doses of the different antifoaming agents have been adjusted to have 0.1% of total solid content, except for the last two which both have 0.2% solid content.

| Antifoaming agent | Dose (%) | % Trapped air (Fresh) | % Trapped air (Aged) |

| Control | 0 | 39 | 44 |

| Product 1 | 0,37 | 39 | 53 |

| EMULTROL DFM AFO-1 | 0,2 | 26 | 35 |

| Product 2 | 0,33 | 35 | 44 |

| EMULTROL DFM AFO-5 | 0,45 | 35 | 45 |

| EMULTROL DFM AFO-24 | 0,2 | 17 | 24 |

| Product 3 | 0,2 | 11 | 22 |

| EMULTROL DFM OLV-24 | 0,2 | 11 | 17 |

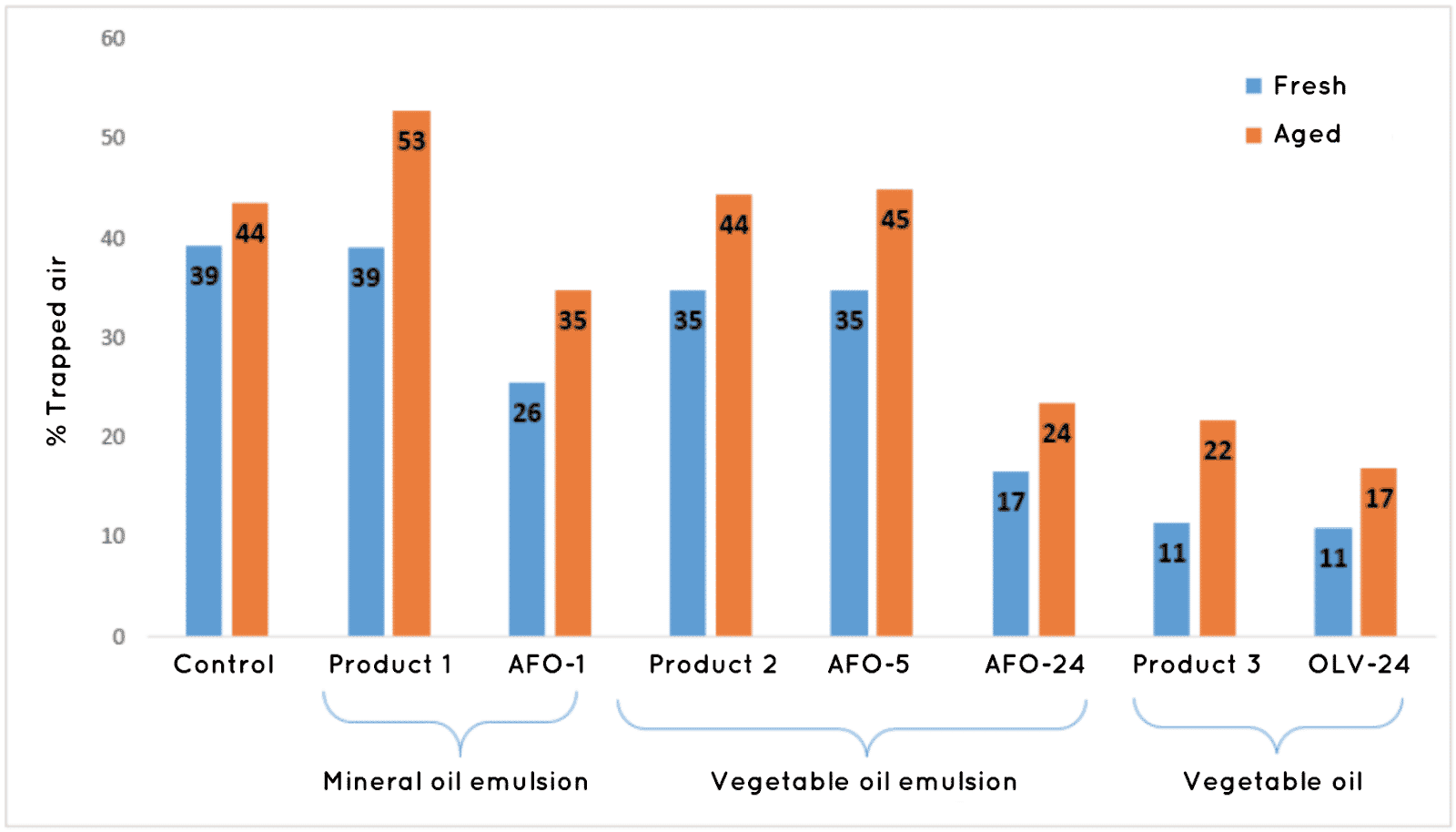

Graph 1. The graph shows the entrapped air of the different antifoaming agents, which corresponds to the entrapped air present immediately after stirring, and the aged air, which corresponds to the entrapped air present after the aging of the dispersion.

Conclusions

First, comparing mineral oil emulsions, EMULTROL DFM AFO-1 showed better performance in both short and long-term effect compared to the market benchmark (sample 1), which did not show any effect or even had more trapped air than the control test.

Regarding vegetable oil emulsions, EMULTROL DFM AFO-24 has a better deaeration effect than the market reference and EMULTROL DFM AFO-5.

Finally, if we compare the effectiveness of vegetable oil based products, EMULTROL DFM OLV-24 shows better long-term deaeration performance compared to the competitor’s product.

For over 75 years, at Concentrol we have worked with a team of expert technicians who help us design and produce the best value for money solutions. Thanks to this important work in our laboratories, we can produce products that meet the needs of our customers and reach more than 82 countries and 5 continents.

Author: Lorenzo Rico, Technical Manager of Concentrol.