COATINGS FOR THE CHEESE SECTOR

Coating cheese, a technique used during the cheese making, plays an important role in packaging and appearance of the final product.

The cheese can be covered during various production process stages.

Before and during the ripening process

Regulation of moisture loss during the ripening process of the cheese and protection against unwanted growth of microorganisms such as molds and yeasts.

After the ripening process

Protection against microorganisms (molds and yeasts) and other contaminants. Protection against mechanical damage of the rind during transport and distribution. And specific final appearance is obtained, such as a particular colour.

THE VIPLAST RANGE

The use of our VIPLAST product range VIPLAST is a suitable way of cheese conditioning, improving the appearance of the piece during the ripening, storage and sale.

It is a surface treatment which offers the advantages of a protective external coating without migration into the cheese. The taste and the organoleptic properties of cheese are not affected in this way.

The following main features of our cheese coatings are of interest:

- Protection of the rind against microbial defects caused by molds and yeasts.

- Protection against mechanical damage of the rind during ripening (surface cracking) and transport.

- Reduction of excessive weight loss of the cheese (dehydration) without affecting the ripening process, decreasing moisture loss also means revenue loss in comparison with untreated cheese.

- Positive influence on the desired flavour, texture, consistency and appearance of the cheese is noted.

- Standardization of cheese quality.

Our VIPLAST range not only includes plastic coatings but also edible ones, based on food additives such as fatty acid esters, natural gums or celluloses.

PLASTIC COATINGS

-

- The range of PLASTIC coatings is perfectly suited to needs such as the process of cutting and portioning cheese, the need for fast drying, adequate moisture resistance and vacuum packaging.

- They do not penetrate the product and they regulate the ripening process of the cheese without affecting the smell or the taste of the treated piece.

- The coating finish can be shiny, satin or matt.Cutting wedges (entrainment of particles) drying rate and moisture resistance (vacuum packing) can be adjusted in different formulations.

NATURAL COATINGS

- The range of NATURAL coatings is based on food additives (with code E according to EU Regulation No. 1333/2008). In this group ACG coatings, based on aqueous emulsions of E-472a (acetic acid esters of mono and diglycerides of fatty acids) are worth mentioning – and also R or RC coatings, which are formulated with gum(E-410-415) and/or cellulose (E-460-466) in aqueous solution. R or RC coatings, formulated with permitted preservatives for the external treatment of cheese, can be considered edible, together with coated cheese.

- Greater permeability than plastic coatings, speeding up the ripening process.

- Natural, handmade appearance.

- Easy elimination, making machinery and equipment easier to clean.

On customer request, the addition of preservatives blends to the VIPLAST range (based on natamycin, sorbates and other food additives) offers protection of the cheese against molds and yeasts.

Besides, there is an extensive catalogue of colours for painting the cheese, with a shiny, satin or matt finish.

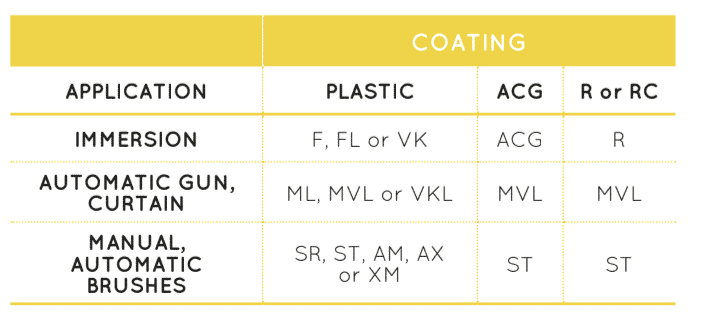

Our VIPLAST coatings range can be adjusted to any system of coating application. The following table shows the nomenclature according to the application and the type of coating.

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.