At Concentrol we work every day to offer the best solutions to our clients. One of the sectors in which we work the most is cheese. The company’s Food Processing Aids Division is specialized in the manufacture of products for the final treatment of food, especially focused on protection against the unwanted growth of microorganisms. In this area, the manufacture of coatings for cheeses stands out. Following is a review of the issue of choosing preservatives, the regulatory framework that applies and other important factors that must be taken into consideration.

Unwanted yeast and mold growth is one of the biggest problems facing the food industry and, in particular, the cheese industry.

Cheese is food that undergoes a curing process, that is, maturing over time. During this process, microorganisms found in the environment and on the surface of the cheese evolve, grow and come to colonize parts or the whole surface of the cheese.

The technological alternative that currently exists and is used in the cheese industry —in those cases in which it is intended to avoid the unwanted growth of mold and yeast— is the surface treatment of cheeses. It is a coating, a coverage that contains preservatives. At European and American level, food regulations specify which preservatives are allowed, as well as their use limitations. It is not possible, considering that these are positive lists, to use other preservatives or active ingredients than those previously evaluated and authorised by the food authorities.

The EU Regulation No. 1333/2008 is the reference framework in the European Union on food additives and their uses:

REGULATION (EC) N * 1333/2008 OF THE EUROPEAN PARLIAMENT AND COUNCIL

of 16 December 2008

on food additives

(Text with EEA relevance)

(DO L 354 of 31.12.2008, p. 16)

Amongst the various foods outlined in the regulation, cheese and its subcategories are detailed in point 01.7

| Number | Denomination |

| 01.6.2. | Unflavoured dairy products fermented by the action of living organisms, and their substitutes, with a fat content of less than 20% |

| 01.6.3. | Other creams |

| 01.7. | Cheese and derived products |

| 01.7.1. | Fresh cheese, except products included in category 16 |

| 01.7.2. | Cured cheese |

| 01.7.3. | Edible cheese rind |

| 01.7.4. | Cottage cheese |

| 01.7.5. | Melted cheese |

| 01.7.6. | Cheese-based products (except those included in category 16) |

| 01.8. | Dairy substitutes, including beverage whiteners |

Cured cheeses are included in section 01.7.2

The details of the additives allowed in cured cheeses can be found in the table below:

| E 1105 | Lysozyme | quantum satis | ||

| E 120 | cochineal, carminic acid, carmines | 125 | (83) | only reddish marbled cheese and cheese with red pesto |

| E 140 | chlorophylls and chlorophyllins | quantum satis | only sage derby cheese | |

| E 141 | cupric complexes of chlorophylls and chlorophyllins |

quantum satis | only sage derby cheese, cheese with green or red pesto, cheese with wasabi and green marbled cheese with herbs | |

| E 153 | charcoal | quantum satis | only Morbier cheese | |

| E 160a | carotenes | quantum satis | only orange, yellow and off-white aged cheese |

| E number | Denomination | Max dose (mg/l or mg/kg) | Notes | Restrictions or exceptions |

| E 160b | Annato, bixin, norbixin | 15 | only aged orange, yellow and off-white cheese and cheese

with red or green pesto |

|

| E 160b | Annato, bixin, norbixin | 50 | only Red Leicester cheese | |

| E 160b | Annato, bixin, norbixin | 35 | only Mimolette cheese | |

| E 160c | Paprika extract, capsanthin, capsorubin | quantum satis | only aged orange, yellow and off-white cheese and cheese

with red pesto |

|

| E 163 | Anthocyanins | quantum satis | only reddish marbled cheese | |

| E 170 | Calcium carbonate | quantum satis | ||

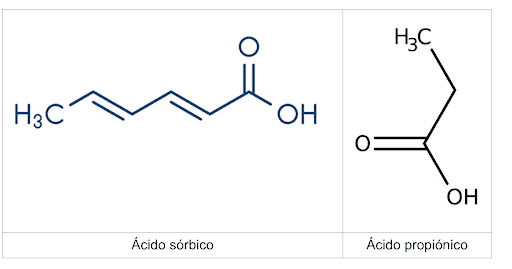

| E 200-202 | Sorbic acid and potassium sorbate | 1000 | 1 2 | only sliced cheese, cut and packed; layered cheese and

cheese with added foods |

| E 200-202 | Sorbic acid and potassium sorbate | quantum satis | only surface treatment of cured products | |

| E 234 | Nisin | 12.5 | 29 | |

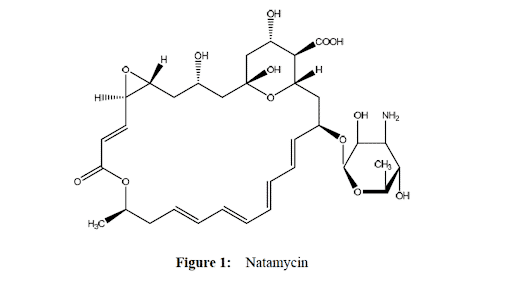

| E 235 | Natamycin | 1 mg/dm2 of surface (not present at 5mm depth) | only surface treatment of uncut hard, semi-hard and semi-soft | |

| E 239 | Hexamethylenetetramine | 25mg/kg residue amount as formaldehyde | only provolone cheese | |

| E 251-252 | Nitrates | 150 | 30 | only hard, semi-hard and semi-soft cheese |

| E number | Denomination | Max dose (mg/l or mg/kg) | Notes | Restrictions or exceptions |

| E 280-283 | Propionic acid and propionates | quantum satis | only surface treatment | |

| E 460 | Cellulose powder | quantum satis | only aged cheese sliced and grated | |

| E 500 (ii) | Sodium acid carbonate | quantum satis | only sour milk cheese | |

| E 504 | Magnesium carbonates | quantum satis | ||

| E 509 | Calcium chloride | quantum satis | ||

| E 551-559 | Silicon dioxide and silicates | 10,000 | only sliced or grated hard and semi-hard cheese

Period of application: until January 31, 2014 |

|

| E 551-553 | Silicon dioxide and silicates | 10,000 | only sliced or grated hard and semi-hard cheese

Period of application: as of February 1, 2014 |

|

| E 575 | Glucono-delta-lactone | quantum satis | ||

| (1) Additives may be added alone or in combination

(2) The maximum dose is applied to the sum and the doses are expressed as free acid. (29) This substance can be present naturally in some cheeses as a result of fermentation processes. (30) In cheese milk, or equivalent dose if added after removing whey and adding water. (83). Maximum aluminium limit from all the aluminium lacquers of E 120 cochineal, carminic acid, and carmines: 3.2 mg/kg. No other aluminium lacquers can be used . For the purposes of article 22, section 1, letter g), of Regulation (EC) No 1333/2008, this limit must be applied from February 1, 2013 onwards. |

||||

From the above list, the only preservatives currently allowed are natamycin (E-235), sorbates (E-200, E-202) and propionates (E-280, E-281, E-282). Natamycin is the most widely used preservative, as it has no effect against bacteria and is very effective against most types of mold and yeast.

Sorbates and propionates are used in combination with natamycin in some cases, since, by themselves, they have very low efficacy.

Soric acid (left) and Propionic acid (right)

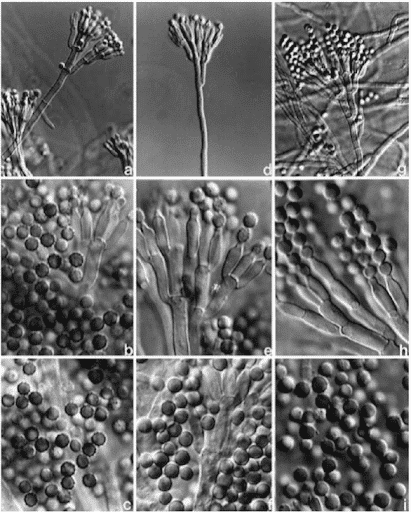

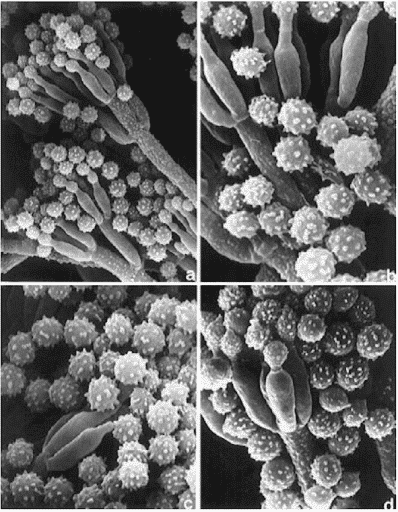

It should be noted, however, that the result in protection against the unwanted growth of mold and yeast is far from optimal. It has been described in literature that a particular mold, “penicillium discolor“, exhibits resistance to the use of the preservative natamycin. Other molds, if the contamination is high, can also grow in the presence of natamycin.

Nomarski phase contrast micrographs of three isolates of Penicillium discolor. a–c. CBS 474.84 (type isolate); d–f CBS 221.92; g–i. CBS 183.88. Magnifications: a, d and g. 600 , all others 1500.

Scanning electron micrographs of critically point dried specimens a–c. CBS 474.84, a. 1900 , b., 4000 , c. 3500; d. CBS 221.92, 3300.

In literature, it has been described that the limiting factor in the use of natamycin is its low solubility in water (approximately 40ppm), and that it is only active in this soluble phase. Thus, amounts of natamycin greater than 40ppm, being not soluble, practically do not provide extra effectiveness.

As an alternative to using the preservatives described above, there are studies that have evaluated the efficacy of other food additives such as lactic acid and acetic acid. Although these additives have preservative efficacy, in the specific case of cheese it is very limited and they have not shown to be effective alternatives. They do not even show effectiveness in combination with traditional preservatives.

As we have seen, the choice of preservatives to prevent the growth of mold and other microorganisms is not easy. At Concentrol we have developed multiple coating solutions with the mission of adapting to the needs of each cheese product. One of our mainstays as a company is research, a fact that allows us to create new solutions and solve possible complications in the cheese-making process.