Cold meats, hams and other processed meats

At Concentrol, based on our experience in the design and production of chemical solutions for the food industry, we have surface treatments for cold meats and hams to guarantee optimum packaging and transport, as well as auxiliary products related to food safety and hygiene.

-

-

- COATINGS

- PRESERVATIVES

- ANTI-FOAMING AGENTS

- OTHER AUXILIARY PRODUCTS

-

COATINGS

The VIPLAST® and PROTILAT® ranges of products include all those coatings for the external treatment of sausages and hams. These regulate and favor the healing process and maturation of the food, while granting fungicide protection against molds and yeasts. They are used for the fixation of spices or simulation of white penicillium in cold meats; And to avoid the formation of white veil in boned ham pieces. All these products can be adapted to different application systems, to meet the specific needs of our customers.

· The range of PLASTIC coatings is based on food additives in accordance with the established by the European Regulation for materials in direct contact with food. (EU Regulation No. 10/2011).

· The range of NATURAL coatings is based on food additives (with E-code according to EU Regulation No. 1333/2008). They are formulated to be considered edible together with the coated food. Among other characteristics, they are easy to clean and in many cases offer a handcrafted appearance without plastic reflections.

PRESERVATIVES

The CONCERVOL® range consists of antimicrobial products for the treatment of meat surfaces and the PROTILAT® range is made up of preservatives for the preparation of salamis, hams and meat

ANTI-FOAMING AGENTS

The EMULTROL DFM® product range is designed for foam control in processes of the food industry. We have a wide range, some of which are Kosher and Halal certified.

OTHER AUXILIARY PRODUCTS

We supply products for food safety and hygiene too: special cleaners, disinfectants and surface lubricants for conveyor belts etc.

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Paints

Our paints range is a whole range of additives and ingredients that give paint the desired finish and properties, improving their manufacturing process, from anti-foaming agents to wax and silicone emulsions, silicone surface additives and other auxiliary products for paints manufacturers.

- ANTI-FOAM AGENTS

- WAX AND SILICONE EMULSIONS

- SILICONE SURFACE ADDITIVES

- OTHER AUXILIARY PRODUCTS

ANTI-FOAM AGENTS

The EMULTROL DFM® range is specifically designed for manufacturers of paints. We offer a complete range based on all technologies to cover any application, condition of use and type of emulsion, with solutions for each need.

WAX AND SILICONE EMULSIONS

The EMULTROL® range consists of a large number of wax and silicone emulsion references. The wax emulsions help to achieve anti-blocking properties, smoothness, matte effect, improve shine, anti-slip, scratch resistance, water-proofing and in general – modify the surface coating of paints. The silicone emulsions are additives that give slip properties, waterproofing and improve resistance to abrasion.

SILICONE SURFACE ADDITIVES

The ORDISOL SWT® range improves wetting without increasing foam formation, using doses of up to ten times less than those of traditional wetting agents. We can also offer special finishes, make a coating smoother, reduce friction or improve resistance to abrasion and scratches etc.

OTHER AUXILIARY PRODUCTS

We can also offer aqueous dispersions of metallic soaps that give a matte, and slip or non-stick effect to your paints. Custom-made polymeric dispersions are also included in our paint formulations.

Contact us for more information

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

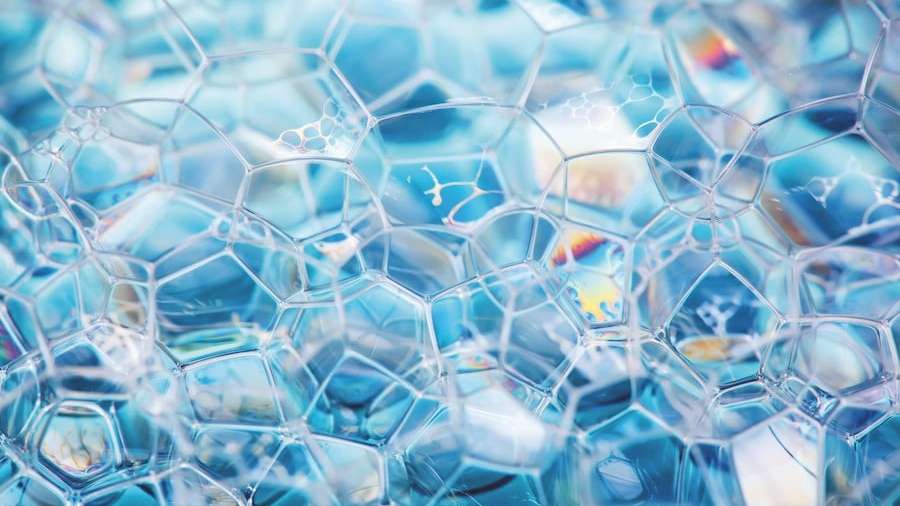

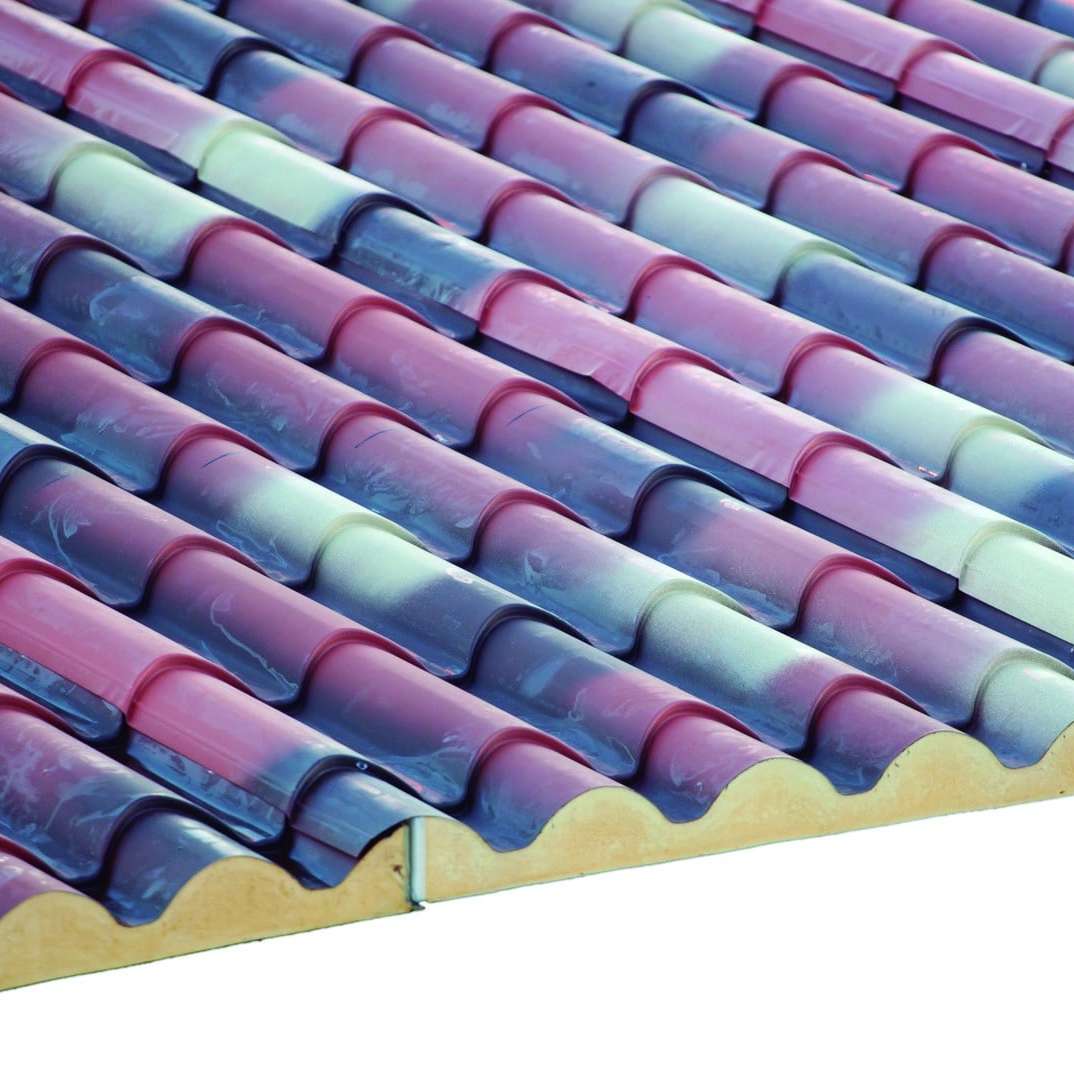

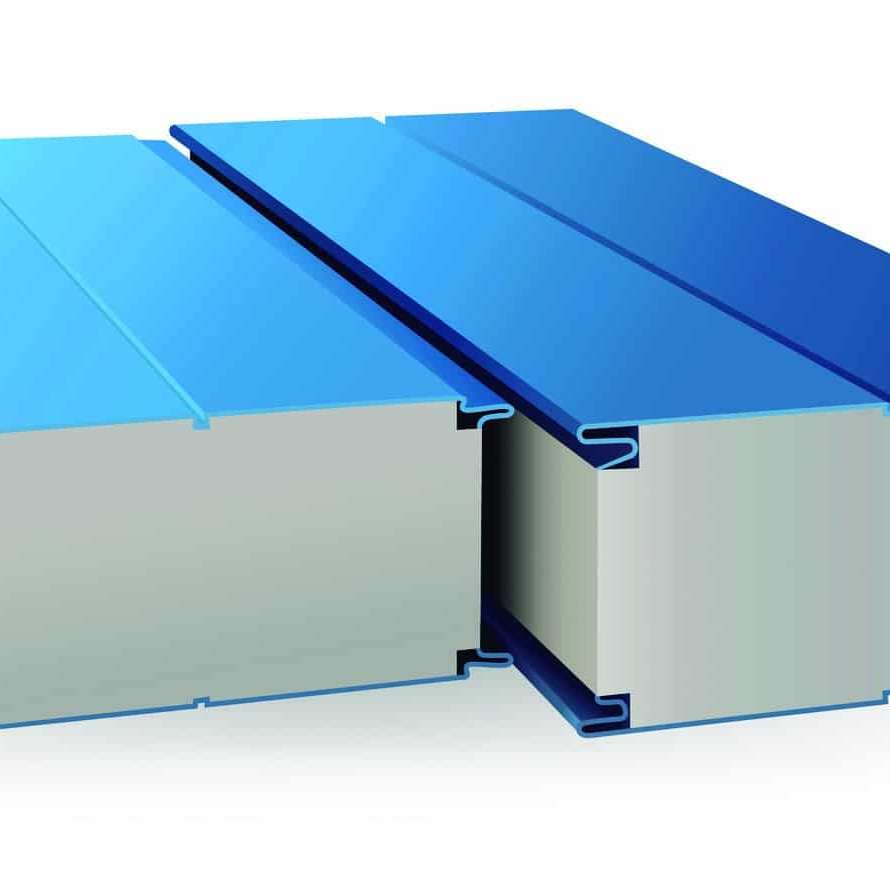

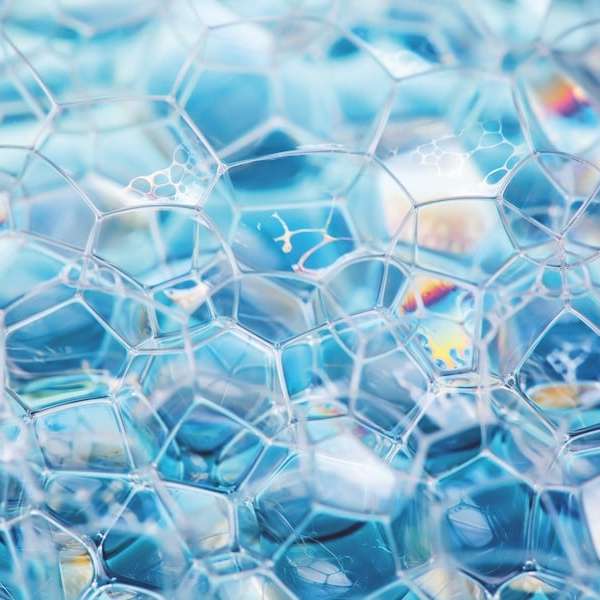

Panels and blocks

It is composed of a complete range of chemical specialties which are essential in the manufacture of injected polyurethane sandwich panels, used to make enclosures in industrial or residential construction. These panels are also used in the insulation industry as they not only provide thermic and acoustic insulation but act as a waterproofing agent and enclosure at the same time because they are lightweight and resistant.

- SILICONE STABILIZERS FOR POLYURETHANE PANELS

- RELEASE AGENTS FOR POLYURETHANE PANELS

- OTHER AUXILIARY PRODUCTS

SILICONE STABILIZERS FOR POLYURETHANE PANELS

The CONCENTROL STB PU® range improves the emulsification of the components of the system, offering sufficient stabilization in the foam expansion process, besides controlling the size and distribution of the cells. In the manufacture of polyurethane panels, the best thermal insulation values are obtained with a fine cellular structure and a maximum of closed cells. Both characteristics can be achieved by choosing the most suitable silicone stabilizer for each formulation.

RELEASE AGENTS FOR POLYURETHANE PANELS

The CONCENTROL® range offers a specific and effective solution for all types of polyurethane panels, including those where special care should be taken regarding the surface coating, high productivity, cost, cleaning of the mold, easy application and protection in the workplace and the environment. We have a wide range of products, with traditional solvent and water based release agents and concentrates which can be diluted. We can also design products to meet our customers’ specific needs.

OTHER AUXILIARY PRODUCTS

We also supply CLEANERS which enable molds to be cleaned easily after long work cycles and SEALERS that not only prevent possible defects but also the sticking of the molded part, reducing work time and costs.

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Footwear industry

It has a wide range of solutions for the process of making soles and shoes of monodensity and soles and shoes bidensitat. In addition, we have products for the different manufacturing processes: direct injection or subsequent assembly.

- RELEASE AGENTS FOR POLYURETHANE SOLES

- STABILIZERS FOR POLYURETHANE FOAMS

- OTHER AUXILIARY PRODUCTS

RELEASE AGENTS FOR POLYURETHANE SOLES

The CONCENTROL® release agent range offers a specific and effective solution for all types of manufacturing techniques for shoe soles: single density or dual density ones, for posterior assembly or direct injection. We offer release agent references for any type of molded polyurethane soles and can meet even the most demanding needs regarding surface coating, high productivity, cost, cleaning of the mold, easy application, absence of organotin compounds and protection in the workplace and the environment. We have a wide range of products, with traditional solvent based release agents, concentrated for dilution and water base ones. We can also design products to meet our customers’ specific needs.

STABILIZERS FOR POLYURETHANE FOAMS

The CONCENTROL STB PU range improves the emulsification of the components of the system, offering sufficient stabilization in the foam expansion process and optimal cell opening, besides control of the size and distribution of the cells. Meets the requirements of foam manufacturers.

OTHER AUXILIARY PRODUCTS

We also supply CLEANERS that enable molds to be cleaned easily after long work cycles and SEALERS to make it easier to restart molding in clean molds, therefore reducing work time and costs.

For more information, consult the video or the catalogue of the footwear sector of Concentrol.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Polyurethane Systems

Polyurethane systems consist of two components; one of them is a mixture of polyols with additives and the other is a diisocyanate.

- STABILIZERS FOR POLYURETHANE

- RELEASE AGENTS FOR POLYURETHANE FOAM

When mixed homogeneously, they react to form polyurethane which presents different levels of hardness – ranging from high (like in elastomers) to soft ( like in the flexible foam used for car seats and furnishing). The majority of these polyurethanes are foams for applications in different sectors of the automotive and furniture industry, construction sector and in the manufacture of injected polyurethane sandwich panels or shoe soles. Our range of products is composed of silicone stabilizers, formulated with polyol and other components (catalysts, water, foaming agents etc.) and release agents for molding processes in which a perfect extraction and finish of the part is required. It is also worth remembering that polyurethane is an excellent adhesive.

STABILIZERS FOR POLYURETHANE

The CONCENTROL STB PU range includes silicone additives for the majority of polyurethane formulations. We have stabilizers for:

- Flexible HR foam (high resilience, frequently used in the automotive and furniture sectors).

- Conventional flexible foam (a wide range of densities, continuous and discontinuous systems).

- Rigid foam (multiple applications).

- Integral foam (microcellular foam and shoe soles).

- Monocomponent foam (OCF).

As there are specific requirements in each application, it is important to choose the right stabilizer to obtain the best properties in the foam:

- in conventional or flexible HR foams, an open cell structure is sought.

- in rigid foams, obtaining a fine, closed cell structure is a necessary requirement for the best results in thermal insulation.

- In rigid foam, the foaming agent that is used should be observed so that the most suitable stabilizer can be chosen in each case.

- in integral foams, it is important to obtain perfect cell distribution and prevent shrinking of the foam.

- in monocomponent foams, the most suitable stabilizers are non – reactive and non-hydrolyzable.

In general, a wide range of stabilizers is really necessary so that we can meet all the needs of manufactures of polyurethane systems.

RELEASE AGENTS FOR POLYURETHANE FOAM

The CONCENTROL® range offers a specific and effective solution for all types of molded polyurethane parts, including those where special care should be taken regarding their appearance, surface coating, high productivity, cost, cleaning of the mold, easy application and protection in the workplace and the environment. We have a wide range of products, with traditional solvent and water base release agents, concentrates that can be diluted and internal release agents. We can also design products to meet our customers’ specific needs.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

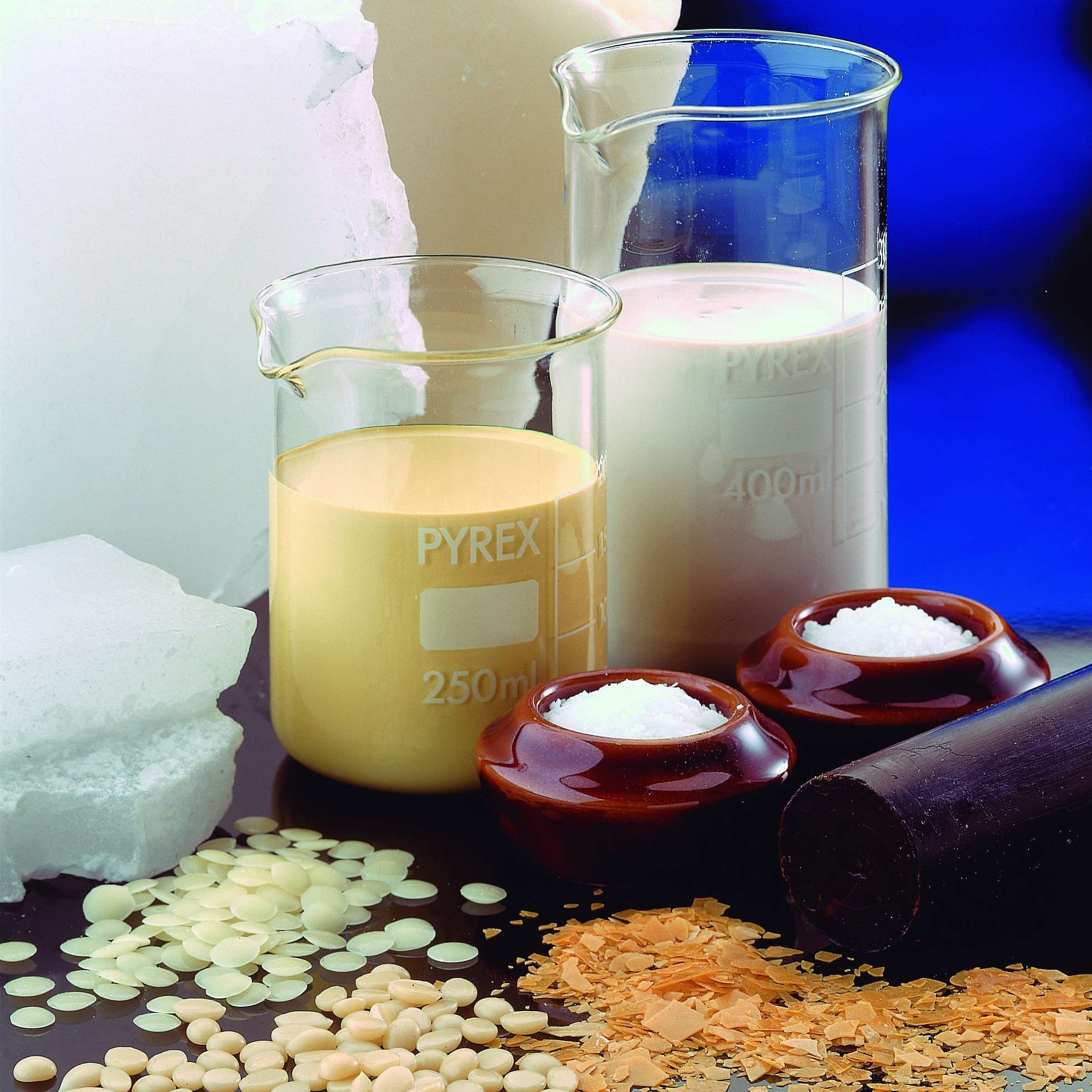

Cheeses

Based on our experience in the design and production of chemical solutions for the food industry, we have surface treatments for cheese to guarantee optimum packaging and transport, as well as auxiliary products related to food safety and hygiene.

-

-

- COATINGS

- ANTIFOAM AGENTS

- OTHER AUXILIARY PRODUCTS

-

COATINGS

The VIPLAST® range includes all those coatings for the external treatment of cheeses during their maturing process. They regulate and promote the curing and maturing process and, with the addition of authorised preservatives, offer fungicidal protection against molds and yeasts. Their use prevents surface cracking and improves the final appearance of the cheese. We have an extensive catalogue of colours, with a gloss, satin or matt finish, adapted to all application systems, to satisfy the specific needs of our customers.

· The range of PLASTIC coatings is perfectly suited to needs such as the process of cutting and portioning cheeses, the need for fast drying, adequate moisture resistance and vacuum packaging.

· The range of NATURAL coatings is based on food additives (with code E according to EU Regulation No. 1333/2008). They are formulated to be considered edible together with the cheese. Among other characteristics, they are easy to clean and in many cases offer a handcrafted appearance without plastic reflections.

ANTIFOAM AGENTS

The EMULTROL DFM® product range is designed for foam control in processes of the food industry. We have a wide range, some of which are Kosher and Halal certified.

OTHER AUXILIARY PRODUCTS

We also have products related to food safety and hygiene: special cleaners to remove dry residues from plastic coatings, disinfectants, sealers for cold storage chambers, surface lubricants for conveyor belts, etc.

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

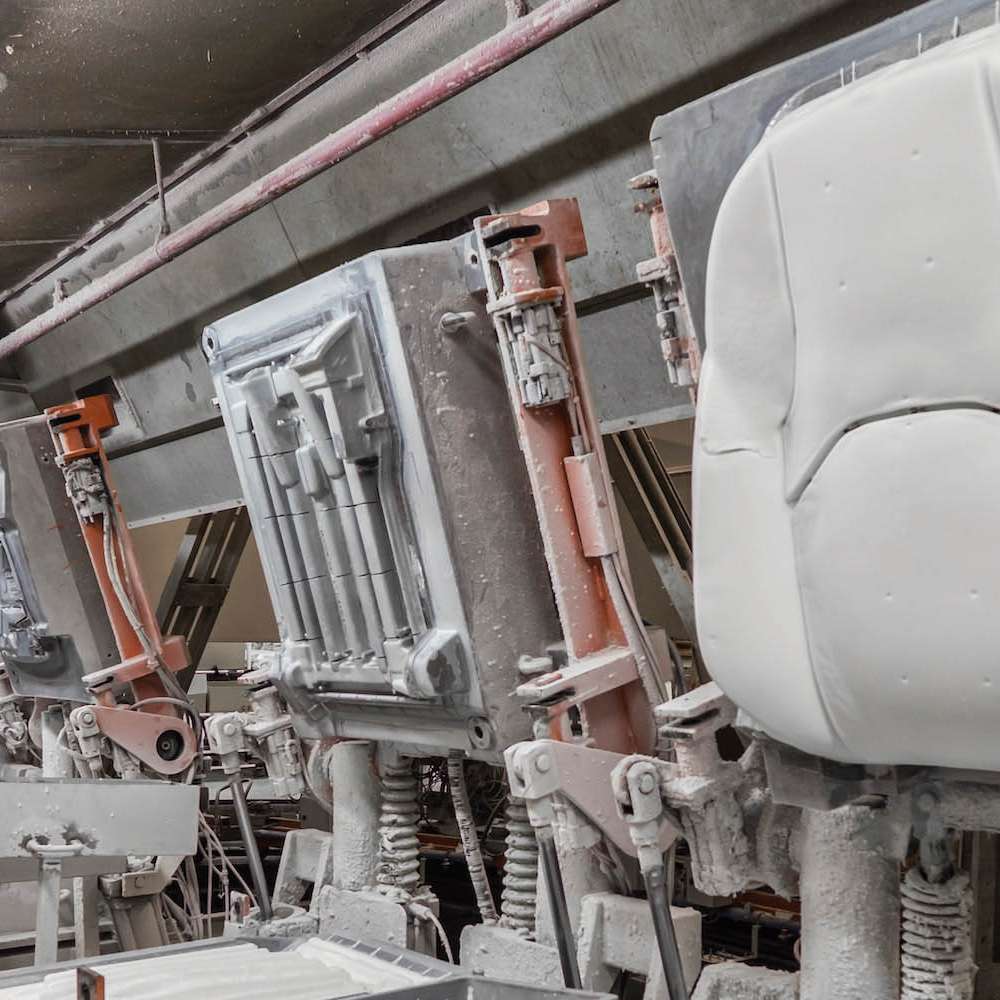

Automotive industry

It is composed of a whole series of chemical specialties which are essential in the manufacture of seats, headrests, armrests, soundproofing, trays, carpets, sunroofs, fuel, oil and air filters, and other molded and injected polyurethane parts, such as steering wheels, glass encapsulation and many other components, spare parts and accessories for the automotive sector.

- RELEASE AGENTS FOR POLYURETHANE FOAM

- SILICONE STABILIZERS FOR POLYURETHANE FOAM

- SURFACE COATINGS

RELEASE AGENTS FOR POLYURETHANE FOAM

The CONCENTROL® range offers a specific and effective solution for all types of molded polyurethane parts, including those where special care

should be taken regarding their appearance, surface coating, high productivity, cost, cleaning of the mold, easy application and protection in the workplace and the environment. We have a wide range of products, with traditional solvent based release agents, concentrated, for dilution and water based. We can also design products to meet our customers’ specific needs.

SILICONE STABILIZERS FOR POLYURETHANE FOAM

The CONCENTROL STB PU® range improves the emulsification of the components of the system, offering sufficient stabilization in the foam expansion process and optimal cell opening, besides control of the size and distribution of the cells. Meets the requirements of foam manufacturers.

SURFACE COATINGS

Concentrol controls a wide range of additives for surface coatings. In addition, it offers each customer the experience of its technical team to study specifically the needs of each case and to be able to advise on the most suitable product to give an impeccable finish to the manufacturer’s product and an excellent quality/price ratio. PRODUCTS: Silicone Surface Additives, Silicone Emulsions, Wax Emulsions, Defoamers, Deaerators, Dispersants or Sliding agents

OTHER AUXILIARY PRODUCTS

We also supply NOISE REDUCTION additives for treatment of polyurethane foam surfaces after demolding, CLEANERS which enable molds to be cleaned easily after long work cycles and SEALERS that not only prevent possible defects but also the sticking of the molded part, reducing work time and costs.

For more information, please consult the video of the automotive sector of Concentrol.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.