Defoamers for the food industry

Defoamers are key products in many industrial processes. Their use allows to increase the production capacity and the quality of the final products. Controlling and reducing the level of foam improves the performance of production processes.

- SILICONE-BASED ANTI-FOAMING AGENTS

- ANTI-FOAMING AGENTS BASED ON VEGETABLE OILS

AREAS OF APPLICATION

Concentrol’s food defoamers cover a wide range of applications, among which we highlight:

- Oils and fats for frying.

- Treatment of frozen, fresh or processed vegetables

- Jams, marmalades or similar.

- Cereals.

- Broths, soups, sauces, protein products.

- Meat brines.

- Beverages, flavoured drinks, cider and some fruit juices (s/ Directive 2001/112/EC)

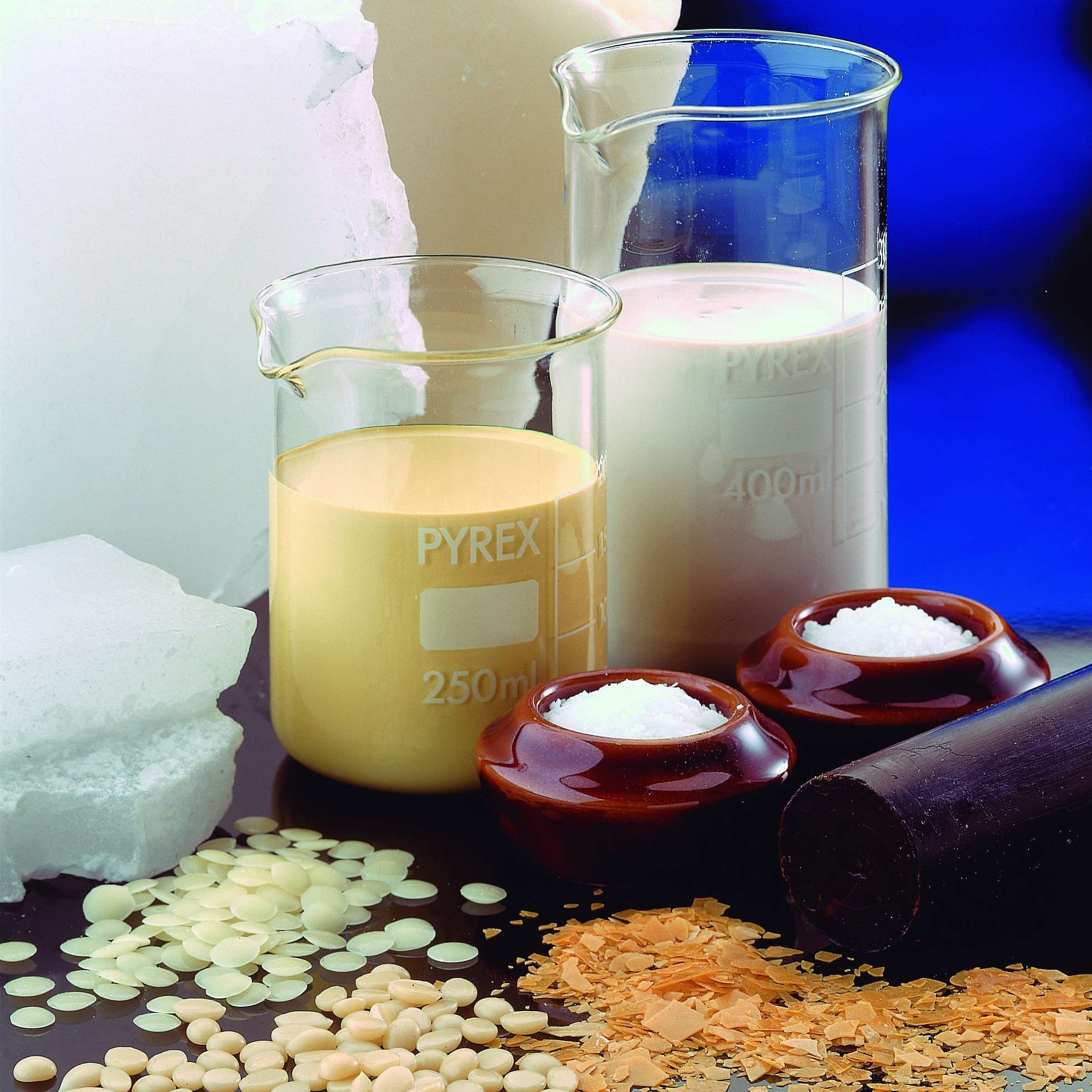

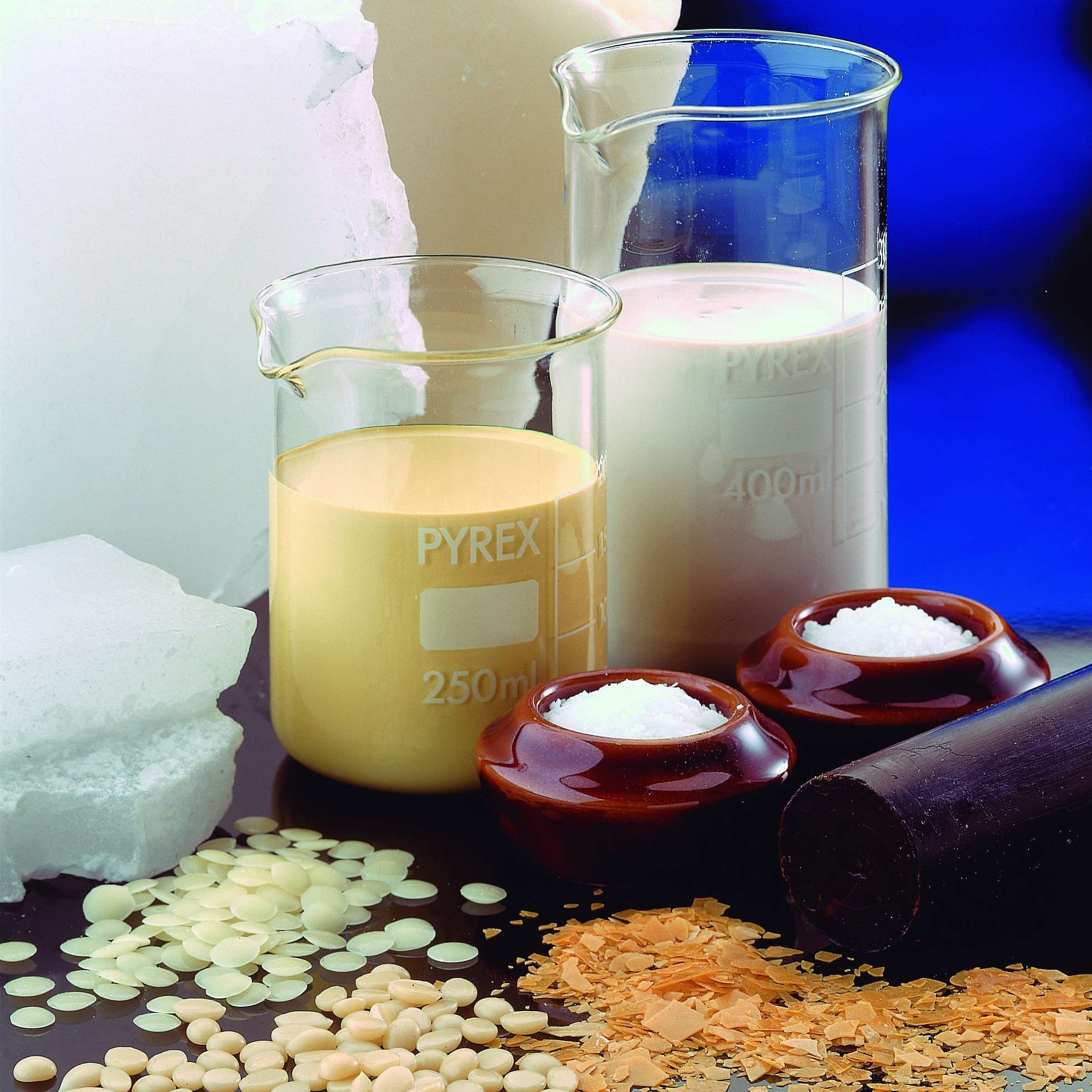

SILICONE-BASED ANTI-FOAMING AGENTS

In the case of the food industry, it is common to use defoamers based on polydimethylsiloxane type silicone emulsions (food code E-900).

The EMULTROL DFM® family of products is specially designed for foam control in food industry processes. We have a wide range, some are Kosher and Halal certified.

In the preparation of deep-frozen vegetables, the defoamer is not added directly to the food, but is used in blanching baths. In these cases, the use of suitable defoamers as food additives is highly recommended, as it is possible that during cooking the vegetables will absorb part of the bath water and all the additives it contains.

In the case of beer, the use of defoamers improves the reproducibility of the waste yeast treatment process, increases the yield in weight per load during transport and reduces the risk of spillage during unloading processes.

ANTI-FOAMING AGENTS BASED ON VEGETABLE OILS

To offer an alternative to silicon-based defoamers, CONCENTROL has formulated the EMULTROL DFM OLV-55 FG product from vegetable oils, which makes its application spectrum wider than that of silicones and makes it suitable for processing dairy products, drinks, fruit, vegetables, soups and meat derivatives, among others. This option has the advantage of maintaining its activity in the long term, which allows for the reduction of anti-foam additions during the process. All this considering that it is a product based on vegetable oil suitable for direct contact with food.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Glass encapsulation and sunroofs

GLASS ENCAPSULATION AND SUNROOFS

CONCENTROL© offers specific products for those manufacturers who fabricate glass encapsulation with RIM/RRIM polyurethane. These are solvent based, water based and hybrid MOLD RELEASE AGENTS specifically made for this application with RIM/RRIM polyurethane. We have available ready-to-use references, concentrates and concentrates for dilution. Thanks to our specialization and know-how, we offer products customized according to the customer’s requirements.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Textile and leather

It is composed of a whole range of additives and ingredients that, not only give textiles and leather the desired finish and properties, but also improve and facilitate the production process.

- ANTI-FOAMING AGENTS

- WAX AND SILICONE EMULSIONS

- SILICONE SURFACE ADDITIVES

- OTHER AUXILIARY PRODUCTS

ANTI-FOAMING AGENTS

The EMULTROL DFM range is specifically designed to eliminate foam generated during all the stages of production of leather and textiles. We have a complete range based on all the technologies.

WAX AND SILICONE EMULSIONS

The EMULTROL range is composed of a large number of wax and silicone emulsion references. The wax emulsions give properties of smoothness, a matte effect, improved shine, anti-slip properties, scratch resistance, water repellence and in general, modification of the surface coating. Silicone emulsions are additives that give sliding properties, shine and water repe-llence.

SILICONE SURFACE ADDITIVES

The ORDISOL SWT range improves wettability without increasing foam formation, using a dose of up to ten times less than the one for traditional wetting agents. It can also add special finishes.

OTHER AUXILIARY PRODUCTS

We supply AQUEOUS DISPERSIONS OF METAL SOAPS that give a matting effect, sliding and non-stick properties.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

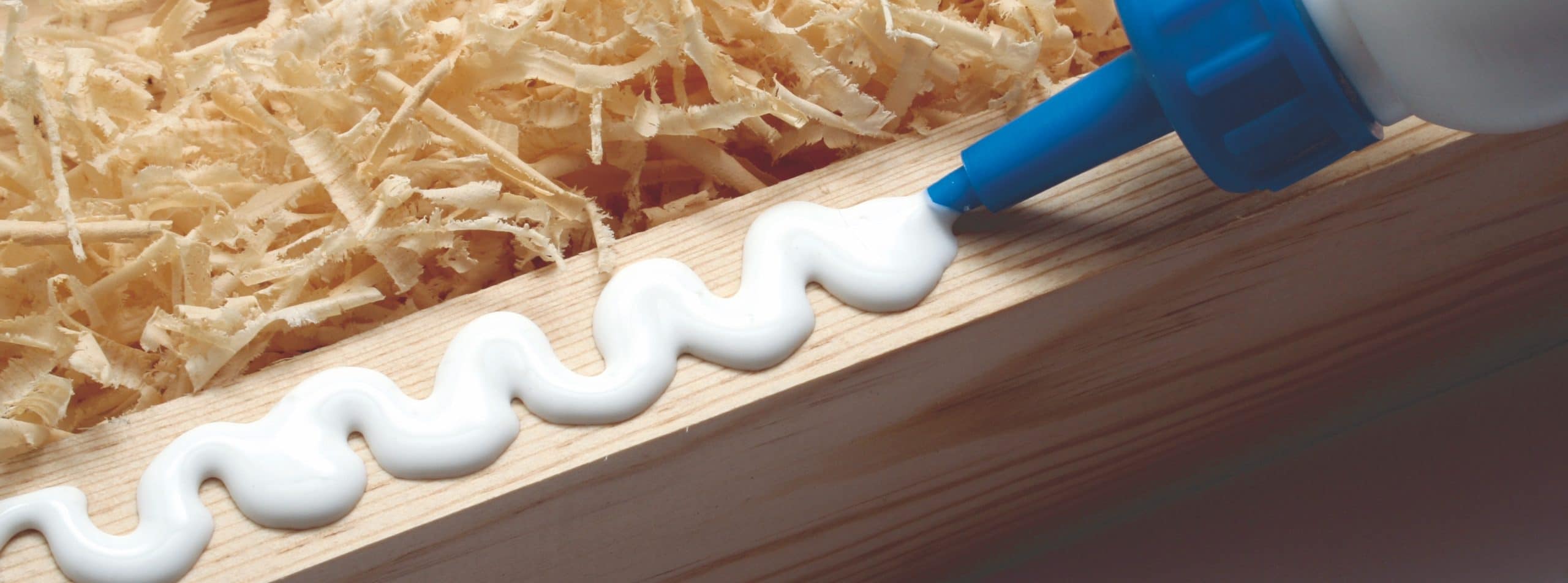

Adhesive manufacturers

It is composed mainly of resin dispersions that modify the cohesion parameters and stickiness of aqueous adhesive formulations, and a series of additives and ingredients that give the final finish and properties desired, to these formulations.

- RESIN DISPERSIONS

- DEFOAMERS

- WAX AND SILICONE EMULSIONS

- SILICONE SURFACE ADDITIVES

- OTHER AUXILIARY PRODUCTS

RESIN DISPERSIONS

The main purpose of the EMULTROL® range of resin dispersions is to improve the properties of cohesion, tack and sticking of adhesives based on polymeric dispersions of acrylic resin, PVA, EVA, SBR, NBR, natural latex, polychloroprene and aqueous polyurethane dispersions. They increase adhesion and tack in non-polar substrates and low energy surfaces, improving their wetting capacity. We have a wide range of microemulsions of different characteristics, origins and types of resins according to their application: esterified acid colophony resins, hydrocarbon resins, terpenophenolic resins, hybrids, etc. Our dispersions are highly stabilized against oxidation and action of ultraviolet rays.

DEFOAMERS

The EMULTROL DFM® range is specifically designed for adhesive manufacturers. We have a complete range based on all technologies. When developing these defoamers for adhesives, special care is taken to achieve the best performance without affecting the wetting of the adhesive formulations.

WAX AND SILICONE EMULSIONS

The EMULTROL® range is composed of a large number of references of metallic soap dispersions and also wax and silicone emulsions. Their use gives water repellency, removable properties and separation of substrates without breakage. In special adhesive formulations, the EMULTROL PS range of silicone micro-emulsions enable properties like adhesiveness and cohesion to be regulated, improving processability. After aqueous dilution, these silicone micro-emulsions are used as sliding and release agents for surfaces and conveyor belts.

SILICONE SURFACE ADDITIVES

The ORDISOL SWT® range improves wetting without increasing foam formation, using doses of up to ten times less than those of traditional wetting agents. We can also offer special finishes, make a coating smoother, reduce friction or improve resistance to abrasion and scratches etc.

OTHER AUXILIARY PRODUCTS

We supply customized POLYMERIC DISPERSIONS as a part of our adhesive formulations.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Paper manufacturers

It is composed mainly of a series of additives and ingredients that give to the paper the final finish and properties required, besides improving the production process .

- DEFOAMERS

- SIZING ADDITIVES

- OTHER AUXILIARY PRODUCTS

DEFOAMERS

The EMULTROL DFM® range is specifically designed for paper manufacturers. We have a range of defoamers that give a high performance without negative effects on cellulose fibre properties.

SIZING ADDITIVES

The EMULTROL range is composed of a large number of sizing additives or wax emulsion references. The wax emulsions give removable properties, smoothness, a matte effect, improved shine, anti-slip properties, scratch resistance, water repellence and in general, modification of the surface coating.

OTHER AUXILIARY PRODUCTS

We supply ANTI-STATIC products for paper and impregnation processes of decorative paper with melamine formaldehyde resins as well as DISPERSANTS for the paper industry. We also offer STEARATE DISPERSIONS which act as internal non – stick coatings in processes of coated thermal paper and AQUEOUS DISPERSIONS OF METAL SOAPS that not only give a matte effect but sliding and non-stick properties

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Inks

It is composed of a whole range of additives and ingredients that give printing inks the desired finish and properties, improving their manufacturing process.

- ANTI-FOAM AGENTS

- WAX AND SILICONE EMULSIONS

- SILICONE SURFACE ADDITIVES

- OTHER AUXILIARY PRODUCTS

ANTI-FOAM AGENTS

The EMULTROL DFM® range is specifically designed for manufacturers of printing inks. We offer a complete range based on all technologies to cover any application, condition of use and type of emulsion.

WAX AND SILICONE EMULSIONS

The EMULTROL® range consists of a large number of wax and silicone emulsion references. The wax emulsions help to achieve anti-blocking properties, smoothness, matte effect, improve shine, anti-slip, scratch resistance, water-proofing and in general – modify the surface coating. The silicone emulsions are additives that give slip properties, waterproofing and improve resistance to abrasion.

SILICONE SURFACE ADDITIVES

The ORDISOL SWT® range improves wetting without increasing foam formation, using doses of up to ten times less than those of traditional wetting agents. We can also offer special finishes, make a coating smoother, reduce friction or improve resistance to abrasion and scratches etc.

OTHER AUXILIARY PRODUCTS

We can also offer aqueous dispersions of metallic soaps that give a matte, and slip or non-stick effect. Custom made polymeric dispersions are included in our painting ink formulations.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Waste water treatment

The EMULTROL DFM range includes those defoamers especially formulated for waste water treatment in many industrial sectors. It is used to eliminate foam in all parts of the process or for its effective control, which prevents product loss caused by unwanted foam formation. We can offer a complete range based on all technologies for the following treatments:

- BIOLOGICAL METHODS

- USE OF PROTEIN

- SPECIAL METHODS

- PHYSICAL-CHEMICAL METHODS

- BIODEGRADABLE RESOURCES

- OTHER METHODS

BIOLOGICAL METHODS

Anaerobic and aerobic microbial metabolism can cause persistent foaming that results in filamentous infestation, fast changes of temperature and pH, changes in the composition of waste water, shock loading or start -up and re start in treatment plants. We have references especially indicated for aerobic or anaerobic sludge digestion systems.

USE OF PROTEIN

References especially formulated for waste water with high protein content, like in scalding and peeling in pig slaughterhouses. We have a range of defoamers, classified as food additives for direct use in food as well as a range of defoamers for direct or indirect food contact. Some of these references are Kosher or Halal certified.

SPECIAL METHODS

We supply references developed for use in severe or very severe conditions, such as defoamers for very alkaline or very acid systems or for those with extremely high temperatures.

PHYSICAL-CHEMICAL METHODS

Waste water treatment has become a necessity for many companies, in order to eliminate contaminants and/or reduce COD values. Unwanted foam often forms in waste water and we supply suitable references for foam elimination in numerous industrial processes.

BIODEGRADABLE RESOURCES

This range has been formulated with non-toxic, biodegradable raw material for processes related to products or services which are 100% ecological.

OTHER METHODS

We also have a wide range of references for different applications and we can design others to meet our customer’s needs.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Mattresses

We offer release agents for foaming and foam cutting, and foam stabilizers for those who formulate their own system.

- STABILIZERS FOR POLYURETHANE FOAMS

- RELEASE AGENTS FOR FOAMS

RELEASE AGENTS FOR FOAMS

The CONCENTROL range is designed for demolding latex, viscoelastic and flexible polyurethane foam used in the manufacture of mattresses and sofa cushions. We have a wide range of water based and solvent based references.

STABILIZERS FOR POLYURETHANE FOAMS

The CONCENTROL STB PU range improves the emulsification of the components of the system, offering sufficient stabilization in the foaming and optimal cell opening, besides control of the size and distribution of the cells. They meet the requirements of foam manufacturers.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Furniture

We offer a wide range of solutions for the production processes of all kinds of furniture and office equipment.

- RELEASE AGENTS FOR FOAM

- STABILIZERS FOR POLYURETHANE FOAM

RELEASE AGENTS FOR FOAM

The CONCENTROL range is suitable for demolding latex, visco-elastic and flexible polyurethane foam used in seating and backrest manufacture. We have a wide range of water base and solvent base references.

STABILIZERS FOR POLYURETHANE FOAM

The CONCENTROL STB PU range improves the emulsification of the components of the system, offering sufficient stabilization in the foam expansion process and optimal cell opening, besides control of the size and distribution of the cells. Meets the requirements of foam manufacturers.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Pressure-sensitive adhesives

It is composed mainly of resin dispersions that modify the cohesion parameters and stickiness of aqueous self-adhesive formulations, and a series of additives and ingredients that give the final finish and properties desired, to these formulations.

- RESIN DISPERSIONS

- ANTI-FOAMING AGENTS

- WAX AND SILICONE EMULSIONS

- SILICONE SURFACE ADDITIVES

- OTHER AUXILIARY PRODUCTS

RESIN DISPERSIONS

The main purpose of the EMULTROL® range of resin dispersions is to improve the properties of cohesion, tack and sticking of self-adhesives based on polymeric dispersions of acrylic resin, PVA, EVA, SBR, NBR, natural latex, polychloroprene and aqueous polyurethane dispersions. They increase adhesion and tack in non-polar substrates and low energy surfaces, improving their wetting capacity. We have a wide range of microemulsions of different characteristics, origins and types of resins according to their application: esterified acid colophony resins, hydrocarbon resins, terpenophenolic resins, hybrids, etc. Our dispersions are highly stabilized against oxidation and action of ultraviolet rays.

ANTI-FOAMING AGENTS

The EMULTROL DFM® range is specifically designed for self-adhesive paper manufacturers. We have a complete range based on all technologies. When developing these defoamers for self-adhesive paper, special care is taken to achieve the best performance without affecting the wetting of the adhesive formulations.

WAX AND SILICONE EMULSIONS

The EMULTROL® range is composed of a large number of wax and silicone emulsion references. The wax emulsions give removable properties y and, in general, modify cohesion.

The EMULTROL PS® range of polymeric silicone micro-emulsions is especially recommended for self-adhesive formulations and, when added to these, they improve the die-cutting and stamping process of rolls of paper and film.

SILICONE SURFACE ADDITIVES

The ORDISOL SWT® range improves wetting without increasing foam formation, using doses of up to ten times less than those of traditional wetting agents. We can also offer special finishes, make a coating smoother, reduce friction or improve resistance to abrasion and scratches etc.

OTHER AUXILIARY PRODUCTS

We supply customized POLYMERIC DISPERSIONS as a part of our pressure-sensitive adhesive formulations.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.