Concentrol has an extensive experience in the synthesis of silicones in order to adjust the properties to suit the needs of our customers. Silicone additives for coatings can have multiple uses depending on their synthesis and give the customer the control of some attributes to obtain certain properties in the final product. Among other properties, silicone additives can be used to control the wetting ability of a coating by controlling the surface tension of the product.

Wetting agents

In the production of paints, inks or coatings, the ease with which they spread on the substrate is a determining factor on the quality of the coating. If when applied or dry the coating does not result in a homogeneous and continuous film this means the wetting properties are not right.

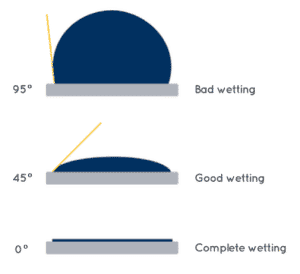

In order to achieve the adequate wetting levels, one of the most used methods is to add wetting additives to the product. Concentrol has developed the ORDISOL SWT range of silicone wetting agents for coatings. These additives are organo-functional silicones, most of them composed of non hydrolysable polyether-polysiloxane copolymers. Their active components are surface-active substances that dissolve in the mixture making it possible to control the contact angle between the coating and the substrate, thereby achieving take control of the surface tension of the liquid.

Figure 1: Wetting according to the contact angle between the coating and the substrate

The ORDISOL SWT range of wetting agents is formulated based on silicones, as they have a better cost-efficient performance than fluorocarbon-based wettings and are also more environmentally-friendly. The silicone molecules move very easily, so they provide lower levels of surface tension to the liquid. In addition, its efficiency is very high at very low concentrations, with commonly used doses below 1% of the total formulation. They also have a high compatibility with most formulations of inks or coatings, and therefore do not generate defects such as craters or “orange peel”.

Within the ORDISOL SWT range, Concentrol has also developed what we call super-wetting agents based on non-ionic copolymer trisiloxane structures. The wetting power of these is much higher, reducing up to 3 to 4 times the surface tension of the water. These, however, lack properties that common wetting agents do have, such as resistance to abrasion, anti-blocking properties, better sliding, etc.

Competitiveness in the synthesis

The wetting properties provided by each of the additives incorporated into coatings vary depending on the composition of the dispersion. It is therefore key in designing additives to have full control of their synthesis.

Concentrol has over 75 years experience in the design and manufacturing of chemical specialities. Throughout the years we have made a great commitment to research and innovation in order to provide our customers with the best solutions for their chemical needs. In the case of silicone additives, Concentrol’s experience is reflected in the ability to control the synthesis of the additive. Thanks to Concentrol’s capacity to synthesize silicone additives, wetting agents are designed to match precisely the properties required for each customer.

Wetting tests

Surface tension:

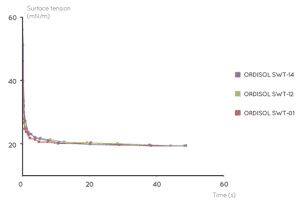

Concentrol laboratories have conducted studies to understand the wetting efficacy of some of our references. In particular we provide a detailed study on a super-wetting reference based on trisiloxane structures and their effect on the surface tension of water. To study this, 1g of super-wetting agent (references ORDISOL SWT-01, SWT-12 and SWT-14) is added to 100 ml of water at 20ºC. The results are calculated by the bubble pressure method. The surface tension is measured in strength for length (N · m-1).

Figure 2: Evolution in time of the surface tension.

We can see thatsuper-wetting references reduced surface tension to 19.5 mN / m (20ºC) in water. The wetting power demonstrated by these references is very high if we consider that the surface tension of the water is around 75 mN / m and usually wetting agents lower the surface tension of water to 40 to 50 mN / m.

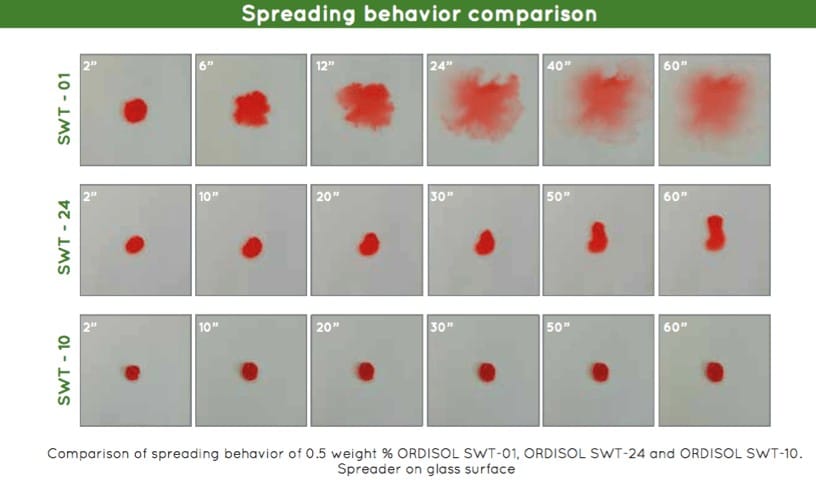

Comparison of the behavior of the dispersion:

In our laboratories a visual test has been done using a concentration of 0.5% of wetting agents in water with dye to visually analyze the behavior of the dispersion. A drop of mixture is placed on a glass surface to see how it spreads on the surface as time passes.

The test was conducted on three different references, ORDISOL SWT-01 and ORDISOL SWT-24, considered super-wetting agents, and ORDISOL SWT-10 a wetting reference.

Through the visual test, we can conclude that the reference classified as super-wetting, ORDISOL SWT-01, has higher levels of wetting, but that does not necessarily result in a better in performance. Depending on the desired properties, we might want to choose a less wetting reference, such as ORDISOL SWT-10, whose wetting power is not as high as SWT-01 but provides additional properties, including better control of brightness, control of the foam, better fluidity of the liquid, anti-crater compatibility, etc.

You can read about the properties of each of our wetting agent references in our new catalog of silicone additives for coatings.

Concentrol studies the case of each individual client and conducts tests to provide the most appropriate solution for their requirements. With full control of the synthesis of wetting agents, references are designed with different properties and levels of compatibility, so that the client has at their disposal solutions that ensure the best quality in their inks, paints and coatings.