It is composed of a whole range of additives and ingredients that give printing inks the desired finish and properties, improving their manufacturing process.

- ANTI-FOAM AGENTS

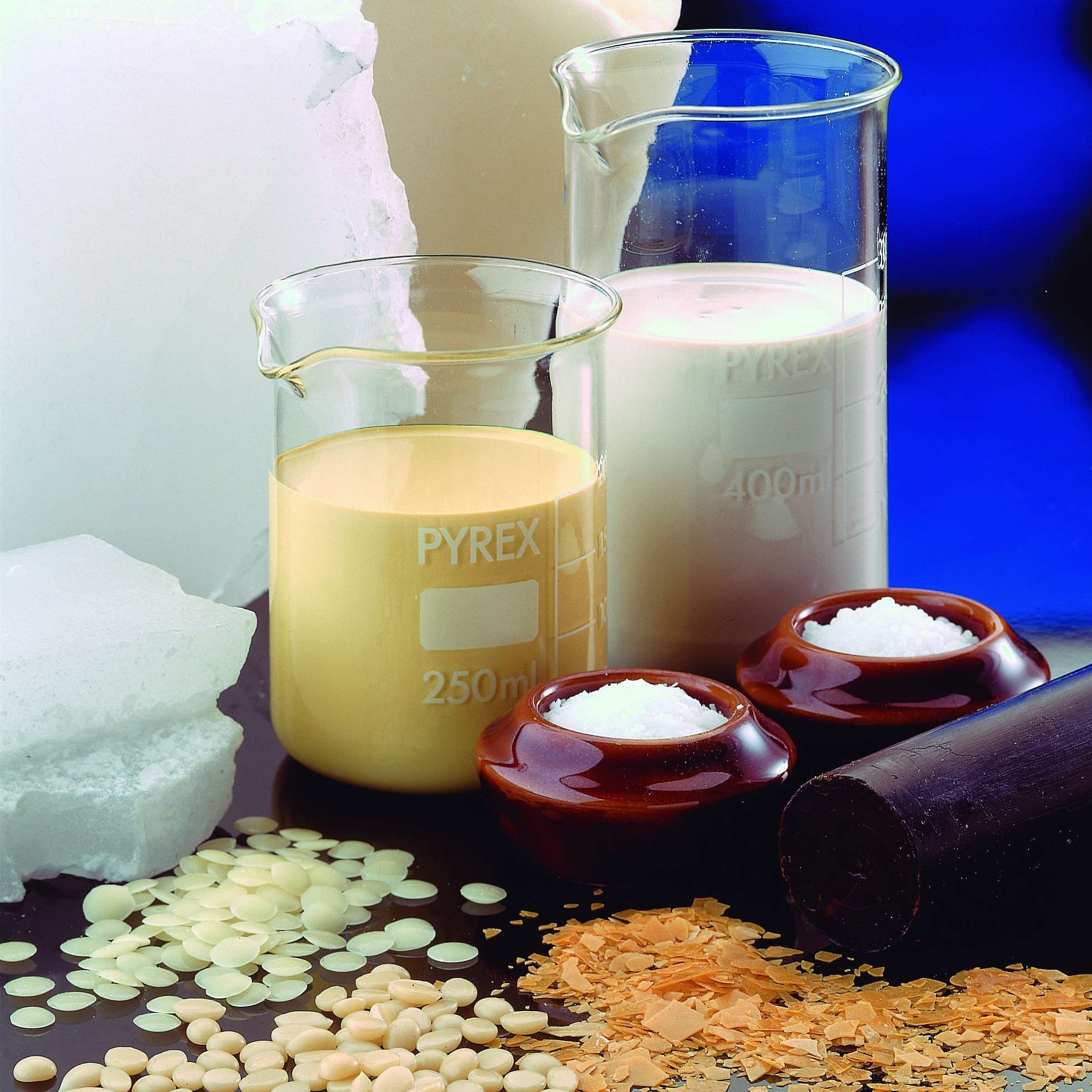

- WAX AND SILICONE EMULSIONS

- SILICONE SURFACE ADDITIVES

- OTHER AUXILIARY PRODUCTS

ANTI-FOAM AGENTS

The EMULTROL DFM® range is specifically designed for manufacturers of printing inks. We offer a complete range based on all technologies to cover any application, condition of use and type of emulsion.

WAX AND SILICONE EMULSIONS

The EMULTROL® range consists of a large number of wax and silicone emulsion references. The wax emulsions help to achieve anti-blocking properties, smoothness, matte effect, improve shine, anti-slip, scratch resistance, water-proofing and in general – modify the surface coating. The silicone emulsions are additives that give slip properties, waterproofing and improve resistance to abrasion.

SILICONE SURFACE ADDITIVES

The ORDISOL SWT® range improves wetting without increasing foam formation, using doses of up to ten times less than those of traditional wetting agents. We can also offer special finishes, make a coating smoother, reduce friction or improve resistance to abrasion and scratches etc.

OTHER AUXILIARY PRODUCTS

We can also offer aqueous dispersions of metallic soaps that give a matte, and slip or non-stick effect. Custom made polymeric dispersions are included in our painting ink formulations.

RESEARCH BLOG

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.