With the goal of continuously enhancing its solutions, Concentrol has a specialized department comprising professionals from various specialties. This team is exclusively dedicated to conducting comparative studies aimed at optimizing and improving chemical solutions, striving to create more complete products with superior properties for each professional sector.

Recently, the Concentrol R+D+i team conducted an investigation to evaluate the effectiveness of different defoamers over time in an ecological softener available in the market. The defoamers tested included: EMULTROL DFM OLV-55 FG, EMULTROL DFM DV-1 and EMULTROL DFM DV-1 S.

| Antifoam | Base | Solids, % |

| EMULTROL DFM OLV-55 FG | Vegetable oils | 100 |

| EMULTROL DFM DV-1 | Silicone | 17 |

| EMULTROL DFM DV-1 S | Silicone | 28 |

To assess the effectiveness of these defoamers, macrofoam tests based on the gas injection method were performed. A 20% aqueous solution of eco-softener without defoamers served as the foaming medium. Additionally, the surface appearance of the softener was compared with each of the defoamers used.

Concentrol methodology

The first step of the study involved the gas injection method. 200 mL of softener were measured in a 1000 mL beaker at an ambient temperature of 25 °C, with magnetic stirring at 400 rpm. Subsequently, a dose of 0.025% of the corresponding antifoam was added (equivalent to a single drop). The preparation was visually monitored to detect possible incompatibilities, and gas was injected through a gas diffuser (Pressure 1 kg/cm² and flow rate 0.1 L/min). The volume of foam formed was measured at 30-second intervals for up to 15 minutes.

The second step consisted of analyzing the surface appearance. Prior to gas injection and after adding the drop of antifoam, the mixture was gently stirred with a laboratory stirrer to incorporate the antifoam. After standing for 30 seconds, the surface appearance of the 20% aqueous softener dilution was compared with each of the antifoams.

Study results

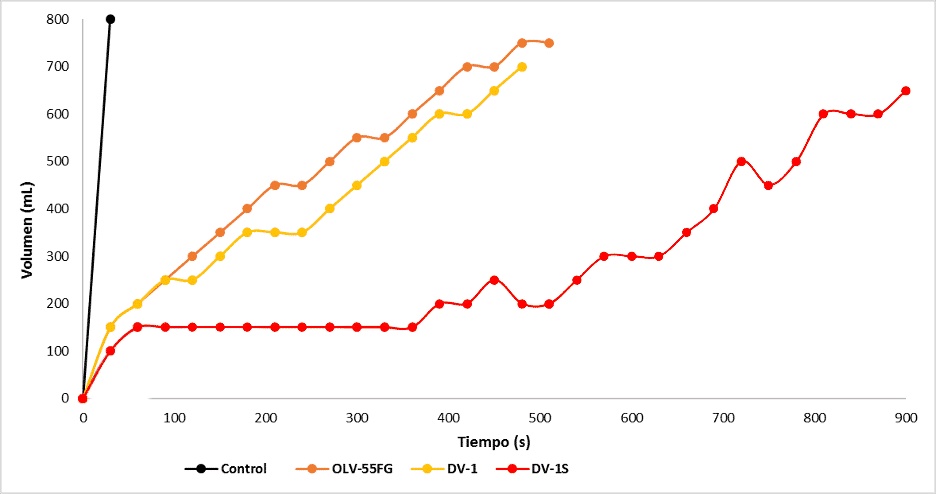

The graph illustrates the difference in foam volume formed over time with different defoamers on a 20% softener base.

As observed in the control test, represented with a black line, a rapid increase in foam volume occurs, whereas in the tests with the different Concentrol antifoams, a consistent foam level can be maintained without significant differences in the first two minutes.

The conclusions drawn from this study are as follows:

- In the long term, defoamers with moderate performance are EMULTROL DFM DV-1 and EMULTROL DFM OLV-55 FG.

- On the other hand, the best defoamer is EMULTROL DFM DV-1 S, a reference that exhibits good long-term efficiency.

Regarding the surface appearance of the softener, the table below provides details on the results with the different defoamers:

| Antifoam | Surface Aspect Observation |

| EMULTROL DFM OLV-55 FG | Disperses very well, indistinguishable from control |

| EMULTROL DFM DV-1 | Disperses very well, indistinguishable from control |

| EMULTROL DFM DV-1 S | Disperses very well, indistinguishable from control |

The best Concentrol formulation

After studying various aspects of these defoamer references for ecological softeners, Concentrol professionals have arrived at the following conclusion:

- The EMULTROL DFM DV-1 S defoamer presents the most desirable characteristics in terms of effectiveness and visual aspect for the ecological softener.

Additionally, it is worth mentioning that silicone-based defoamers are considered ecological since their raw material, silicone, is inert towards living organisms and easily degrades in the environment.

Alternatively, the EMULTROL DFM OLV-55 FG defoamer is also presented as an ecological defoamer solution due to its origin from renewable sources, although it is not as efficient as EMULTROL DFM DV-1 S, which is silicone-based.

At Concentrol, we firmly believe that research makes us better, more professional, and more competent, which is why we innovate with chemistry to add value and ensure the present and future well-being of society.