Introduction

At the last PU China Shanghai trade fair, where Concentrol exhibited its latest innovations, our Dr. Adrià López, specialized in silicone-based surfactants, presented to all attendees how significantly low emissions and low odors can be achieved in the production of silicone-based surfactants for HR molded foams.

First of all, he said that we need to make sure that,

What do we mean by emissions and which ones could we consider as such?

- Chemicals released by a PU foam under certain conditions

- In most cases, temperature is the most important thing. Splashes from a stationary vehicle, for example, can reach up to 120 °C.

- Some chemicals are very volatile. They are released at low temperatures, like some aldehydes and aromatics.

- Others have maximum levels to be taken into account under the global regulations on hazardous chemicals (in 2018, ECHA identified cyclic siloxanes D4, D5 and D6 as SVHCs; their maximum level for these substances in silicone-based surfactants is now < 0.1% by weight for each type).

Can we determine the origin of the emissions?

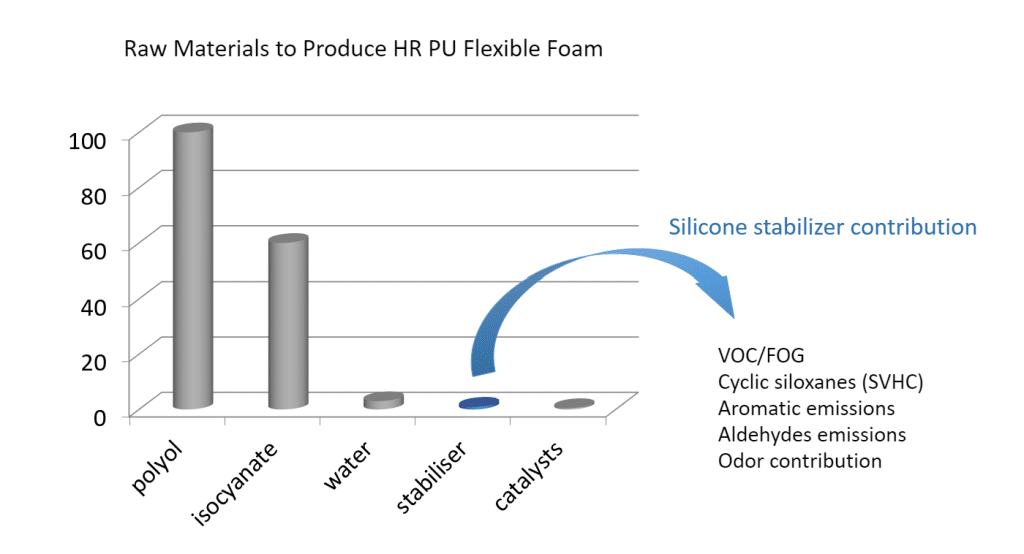

The graph below shows the main raw materials used in the production of flexible polyurethane foam, some of which can contribute to the generation of emissions during the manufacturing process:

The emissions of a foam can come from the different materials used, but the focus is on reducing surfactant emissions.

What methodology is used to analyse emissions?

Various methods can be used to analyse the emission classification:

- Methods of thermal desorption (VDA 278). For the purpose of determining TVOC emissions only.

- “Headspace” analysis. TVOCs are emitted from a sample of PU foam in a closed container.

- Sampling bag. They make it possible to determine the emissions of TVOCs, but also of aromatics/aldehydes.

- Test methods for cameras. We distinguish between microcamera tests (44/144 ml) and small chamber tests (1 m³), which are included in ISO 12219-4.

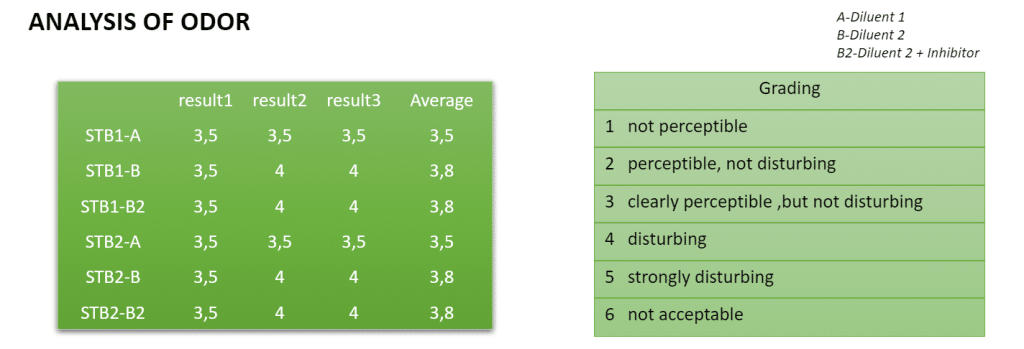

On the other hand, analyses such as VDA270 allow the analysis of odour.

The measuring grades are divided into:

- Imperceptible

- Conspicuous, but not disturbing

- Clear noticeable, but not disturbing

- Disturbing

- Strongly disturbing

- Unacceptable

- Another specific test method for odor analysis is considered the human odor test vs. the e-nose.

The generation of emissions can be determined under various aspects:

- In raw materials and in substances that have not been intentionally added (NIAS). It should be noted that in this case, replacing components does not mean a reduction in odors.

- In the manufacturing process. by-products of the chemical reaction. We can use inhibitors to minimize side reactions.

- Degradation products due to the aging of the foam. This leads to an improvement in the ageing stability of the raw materials.

Volatile Aromatic Compounds

- They can come from aromatic solvents used in synthesis.

- Although there are industrial processes to remove solvents, some traces may remain.

- The raw materials siloxane or polyester are not expected to contain aromatics due to their synthesis pathways.

- The synthesis of silicone surfactants without aromatic solvents is the guarantee that we avoid volatile aromatic compounds in the surfactant.

Concentrol does not use aromatic solvents in its production line.

Volatile carbonyl compounds (aldehydes)

- Volatile carbonyl compounds can be formed by the degradation of certain chemicals.

- Polyethers are the main source of carbonyl compounds due to their oxidative degradation pathway of C-O-C bonds.

- While polysilxanes are related to low MW siloxanes, they are not considered a source of carbonyl compounds due to their chemical structure.

- A high content of siloxane in a surfactant and a low content of polyester help reduce carbon emissions.

Methodology

Analysis of silicone-based surfactants

The main aspects that we must take into account when making a silicone-based surfactant are:

- Analysis of the surfactant emissions:

- TVOC (Volatile Organic Compounds)

- Aldehydes & Aromatic

- Odor

- PU performance of new generation of silicone surfactants

ANALYSIS OF THE SURFACTANT EMISSIONS

Examples of analytical methods are:

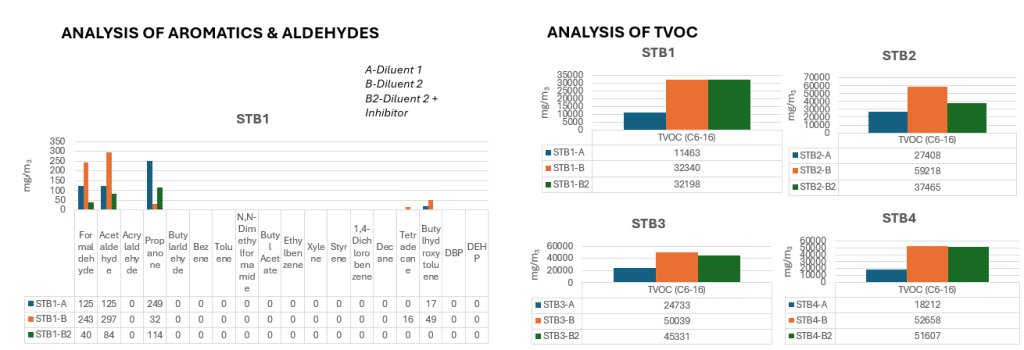

In the previous analytical sample, we shed light on the following aspects:

- Two different diluents were evaluated

- Although they help reduce aldehyde and aromatics emissions, inhibitors do not affect the contribution of odors.

- The yield of diluent A is slightly higher than that of diluent B.

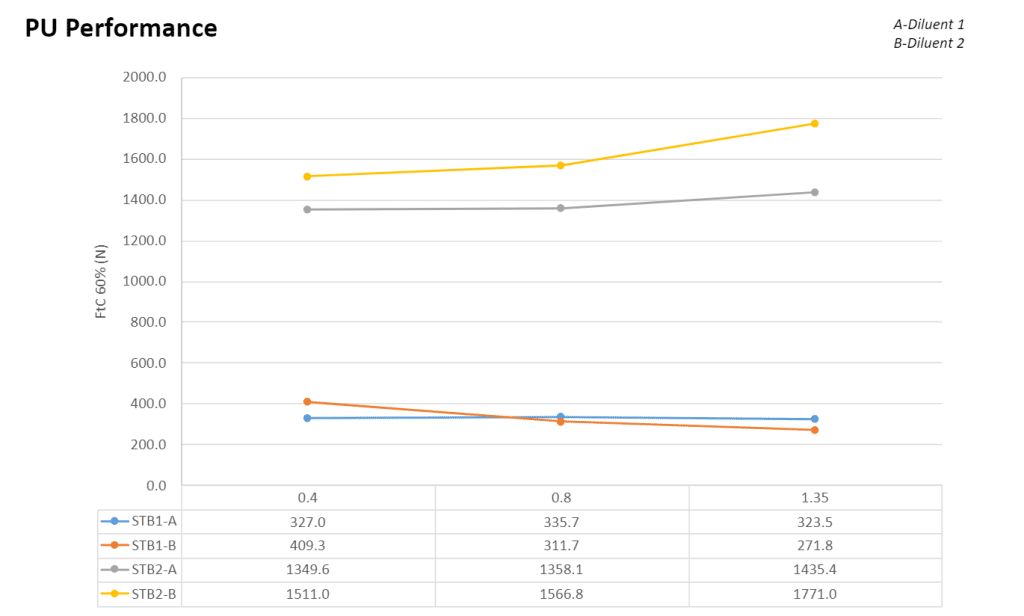

POLYURETHANE PERFORMANCE ANALYSIS

SUMMARY AND KEY CONSIDERATIONS

- The diluent has a direct effect on aldehyde/aromatic emissions and odours

- Inhibitors can help to reduce the aldehydes and aromatic emissions, but not remove completely.

- New doors have been opened to reduce the emissions and odor.

- TVOC are more related by design of silicone surfactant.

- It is possible to reduce the emissions without affect the performance.