Resin dispersions

Resin dispersions

- They improve the parameters of cohesion and sticking of adhesives and self-adhesives based on polymeric dispersions of acrylic resin, EVA, SBR, NBR, natural or synxthetic latex and aqueous polyurethane dispersions.

- They do not contain alkyl phenol ethoxylates or solvents.

- The main use of resin dispersions is to improve the adhesion of polymeric dispersions on non-polar substrates, mainly plastic surfaces although they can be used in applications on porous and polar supports like paper and cardboard.

- They have excellent compatibility with acrylic resin dispersiones EVA, SBR, NBR, latex, polychloroprene and polyurethane.

- Once they have been suitably formulated, they provide very good wetting action – particularly on silicone paper and other types of supports in general.

- The dry film is highly stabilized against oxidation and the action of UV rays. The dispersions are composed of particles with a very small diameter, which facilitates their application with rollers.

- They provide very good mechanical resistance to shear stress.

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Silicone surface additives

Silicone surface additives are well known products as providers of special properties to paints, inks and coatings. These additives are organo-functional silicones, most of them composed of non-hydrolizable polyether-polysiloxane copolymers. These silicone based products differ from traditional silicone oils in several ways: they are easier to use, they are compatible with most coating formulations, and they do not cause typical defects such as craters or recoatability problems.

Like other silicone based additives, its efficiency is very high at very low concentrations, with normal dosages usually well below 1% based upon total formulation.

ORDISOL SWT range of silicone surface additives are the right choice for formulators looking for improved slip, mar resistance, levelling, substrate wetting, anti-blocking properties and gloss enhancement. Most of our range of additives are composed of 100% pure materials in order to provide maximum effectiveness. Being pure silicone surfactants, they are usually compatible with various coating systems such as solvent-borne, solvent-free and aqueous formulations.

Silicone surface additives are also characterized by their ability to reduce the surface tension.

The water based coatings exhibit a high surface tension compared with traditional solvent-borne systems (the surface tension of water is 72.4 mN/m). They exhibit poor substrate wetting compared with solvent based equivalents. This is where silicone surface additives (among other chemicals) play their role modifying the surface properties of waterborne water based coatings.

Some of them, taking advantage of their low molecular weight and “T-umbrella” structure, are classified as super-wetting additives because they are able to reduce the surface tension in water solution to a value close to 19.5-20 mN/m. CONCENTROL develops and manufactures, silicone surface additives and other silicone based products such as organo-functional silicone stabilizers for polyurethane foam and special silicone emulsions for textile, pulp & paper and coatings using proprietary technology.

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Coatings for the meat industry

CONCENTROL has a wide range of products for the meat sector, especially for the external treatment of cold meats and hams. It includes plastic coatings which conform to the European regulation (EU) Nº 10/2011 for direct food contact and natural coatings based on food additives (with code E according to the UE Regulation Nº 1333/2008) formulated to be considered edible together with the coated foods. These products improve the presentation and conservation of the piece and can be coloured at customer request.

COLD MEATS

The meat industry is one of the major economic resources in the agri -food sector, especially the one which specializes in the production of cold meats. Among the huge variety of meat products, the uncooked cured meat range is the one with the most varieties. These products are made by chopping or mincing meat and fat (with or without offal) and adding authorized spices, additives and seasoning. They are packed into natural or artificial casing and then cured.

CONCENTROL participates in the elaboration process of uncooked cured meat by offering several external treatments for the piece, to improve its presentation and conservation.

PEPPER, FINE HERBS AND SPICES

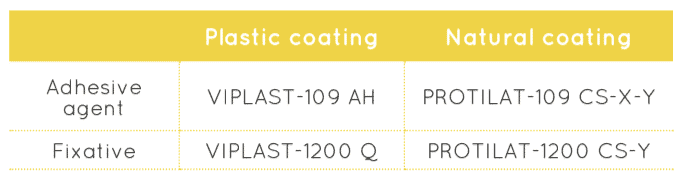

Among the applications of coatings for the meat sector, the use of these coatings as fixing agents for pepper, spices and herbs stands out. It is a very important application and where the coatings formulated by CONCENTROL stand out for many years. Currently, this application is made with edible coatings so that they can be consumed with the sausage and with the pepper or herbs.

There are two groups of coatings, those that act as adhesives and those that act as fixers of spices and pepper in cured sausages or cold meats. Its application is suitable in both artificial and natural intestines and, in some cases, directly on the meat once the intestine has been removed. They offer a natural finish, regulate the ripening process of the cold meats and offer protection against unwanted growth of mold and yeast.

The viscosity, stickiness of the coating, and addition of natamycin can be modified at the customer’s request.

Our references are shown in the following table:

PROTECTIVE EXTERNAL TREATMENT

Nowadays, raw cured meat products are especially appreciated for their appearance, texture and colour. However, one of the problems related to appearance is the unwanted growth of mold on the surface.

As a preventive measure, CONCENTROL supplies natural, edible coatings which can be applied to natural gut and, plastic coatings like VIPLAST-1200 Q, which are applied to artificial casing. These coatings are applied by immersion and give protection against molds and yeasts, as well as giving good adhesion on the product and a natural appearance.

MOLD SIMULATION TREATMENT

In order to give an irregular, white finish on the surface of cold meats equivalent to the natural growth of white Penicillium, CONCENTROL can offer VIPLAST W-171 SF-05 RF. This coating is formulated with food additives that do not cause adverse reactions, according to annex II of Regulation EU 1169/2011.

CURED HAMS

Cured hams are usually sold in a whole piece with the bone, or as a piece from the centre of a boneless ham. One of the main objectives in the production of cured ham is to obtain a product of highest sensorial quality. For this reason, CONCENTROL has developed a range of VIPLAST C-900 ACG pnatural edible coatings for the external treatment of boneless ham. The characteristics of this range are the following:

- They ensure optimal regulation of the ham curing process.

- They prevent the growth of surface mold.

- They minimize oxidation and unwanted growth of mold on the inside of the ham.

- They prevent white film from forming on the surface.

These coatings are formulated with aqueous emulsions of E-472a (acetic acid esters of mono- and diglycerides of fatty acids) and other food additives belonging to group I according to regulation (EU) 1129/2011.

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.