Strategic Market data

The automotive market is currently valued at USD 395 mil milion and is expected to reach over USD 500 billion, registering an annual rate of over 4% during the forecast period. Major manufacturers are focusing on new technologies such as replacement of engine control units to increase the average life of vehicles and improving the life cycle of engines. Within the automotive sector, the seating sector is valued at $80.25 billion and is expected to reach $109.2 billion with a CAGR growth of 5.27% in the coming years. In relation to acoustic materials in the automotive sector, this is estimated at USD 5.13 billion for this year 2024, and is expected to reach USD 6.28 billion by 2029. The expected compound annual growth rate for this period is 4.09%.

Seats Made of flexible polyurethane foam

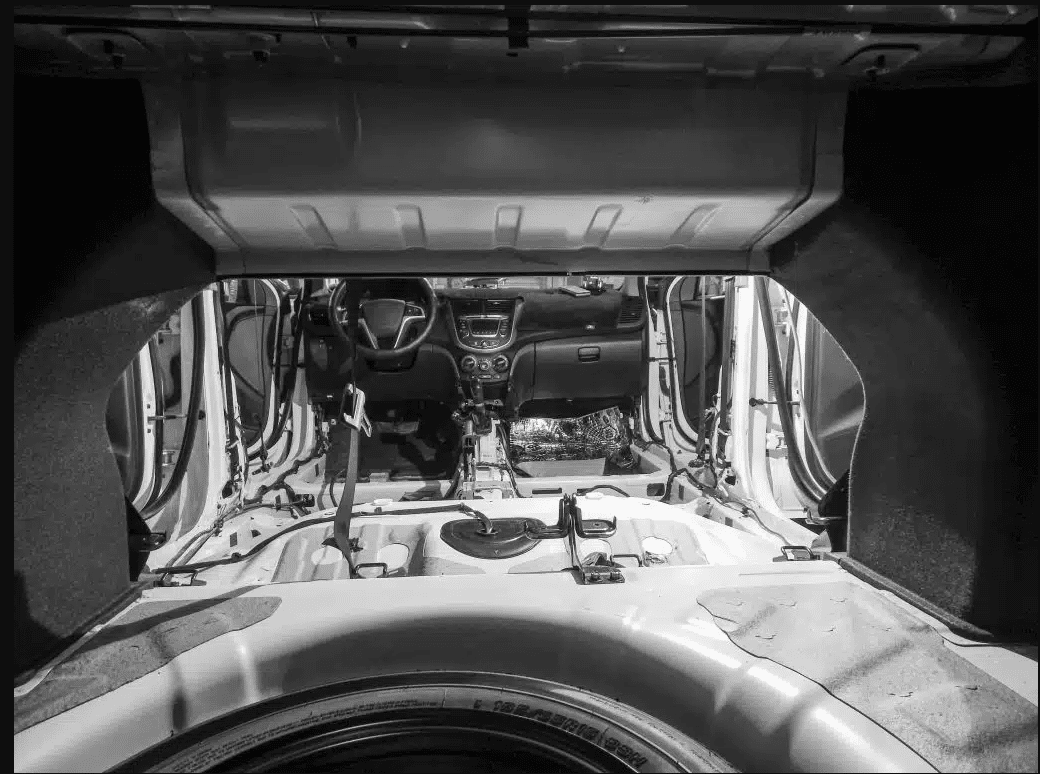

One of the most strategic and main product lines in the automotive sector are release agents, basic in the manufacture of moulded polyurethane foams, such as those used in the manufacture of seats. Due to the very high adhesion properties of PU in its formation process, it is necessary that once the part has been formed, it can be easily removed. This is where Concentrol release agents play an important role for the industry.

Concentrol product range is differentiated between release agents for hot-curing foam and release agents for cold-curing foam.

The main requeriments for an effective demoulding performance of the part are:

- Ease of demoulding

- Progressive cleaning of the mould and its installation

- Smooth and slippery feel, to faciliate sleeving

- Anti-noise effect, especially in the manufacture of soundproofing parts for vehicles

- Surface pore regulation

- Homogeneous finish

- Not detrimental to the bonding of nappas or other materials

Within the specific range of release agents, Concentrol offers those for cold-polyurethane foam parts, such as seats and soundproofing in vehicle manufacturing. The working temperatures are between 45ºC and 65ºC for seats, and between 55ºC and 75ºC in sounfproofing application. It provides an open or closed pore finish on demand and gives the final part a soft touch finish.

Application by spray gun is recommended, especially for water-based release agents, but also effective with airless spray gun or electrostatic system in the case of solvent-based release agents.

Key features of cold polyurethane foam release agents:

- High degree of efficiency and productivity (cost/piece)

- Minimal retrofitting process on existing PU working lines

- Very good surface appearance

- Dry surface finish / post bonding

- High efficiency in the demoulding process

Concentrol solution and value proposition

At Concentrol we offer complete solutions to our customers, where the overall result and service are the main pillars of our DNA to meet the needs of each of them. Along with our range of release agents, we offer to these customrs who are self-formulating manufacturers in the automotive sector, silicone stabilizers or additives that are incorporated into the polyurethane foam with the main objective of facilitating the emulsification of its components, thus improving the necessary stabilization in the expansion process.

As a result, the performance of the final solution provides us with:

- Regulation of the size and uniformity of the cells

- Stability of the foam during the expansion process

- Obtaining foams with low emissions due to their minimal contribution of volatile organic compounds (VOC).

We must be aware nowadays sustainability and the impact of the efficiency of production processes in all types of industries is vital to generate a positive impact on society and the planet.

Therefore, at Concentrol we provide our customers with strategic solutions that:

- Improve the efficiency of processes and quality control thhrough decisions based on Data Analysis

- Detect possible incidents in the production process at an early stage, which allows for proactive maintenance of equipment and effective reduction in machine downtime.

- Optimise the amount of release agent used, through precise monitoring of the flow rate.

- Deliver improved customer satisfaction through recommendations or implement improvements in support through data intelligence.

- Reduce carbon footprint.

It’s at this point Concentrol’s Spray Process Control System, the new spray system with automation and digitalisation ast the cornerstones of its development, which helps to improve the overall efficiency of the equipment:

- Reduces machine downtime

- Improve efficiency

- Improve FRC (First Run Capability)

Concentrol Values

At Concentrol we innovate with chemistry to have a positive impact on society and the planet. We offer chemical solutions and work focused on the best innovative processes to make life easier for our partners and build a more sustainable future.

Trust, Solution and Experience make us stronger to be a reference in the chemical sector.