Stabilizers for polyurethane foam

HR SLABSTOCK FOAM

CONCENTROL surfactants meet the main requirements of HR polyurethane producers:

- WIDE SELECTION OF ADDITIVES in order to offer different stabilizing potency for MDI, TDI/MDI and TDI systems, also providing different ratios in cellular regulation..

- CELL REGULATION and INTERNAL STABILIZATION may be adjusted in order to obtain good quality foams with improved processability.

- LOW EMISSION FOAMS, regarding VOC and fogging, from the point of view of the surfactant.

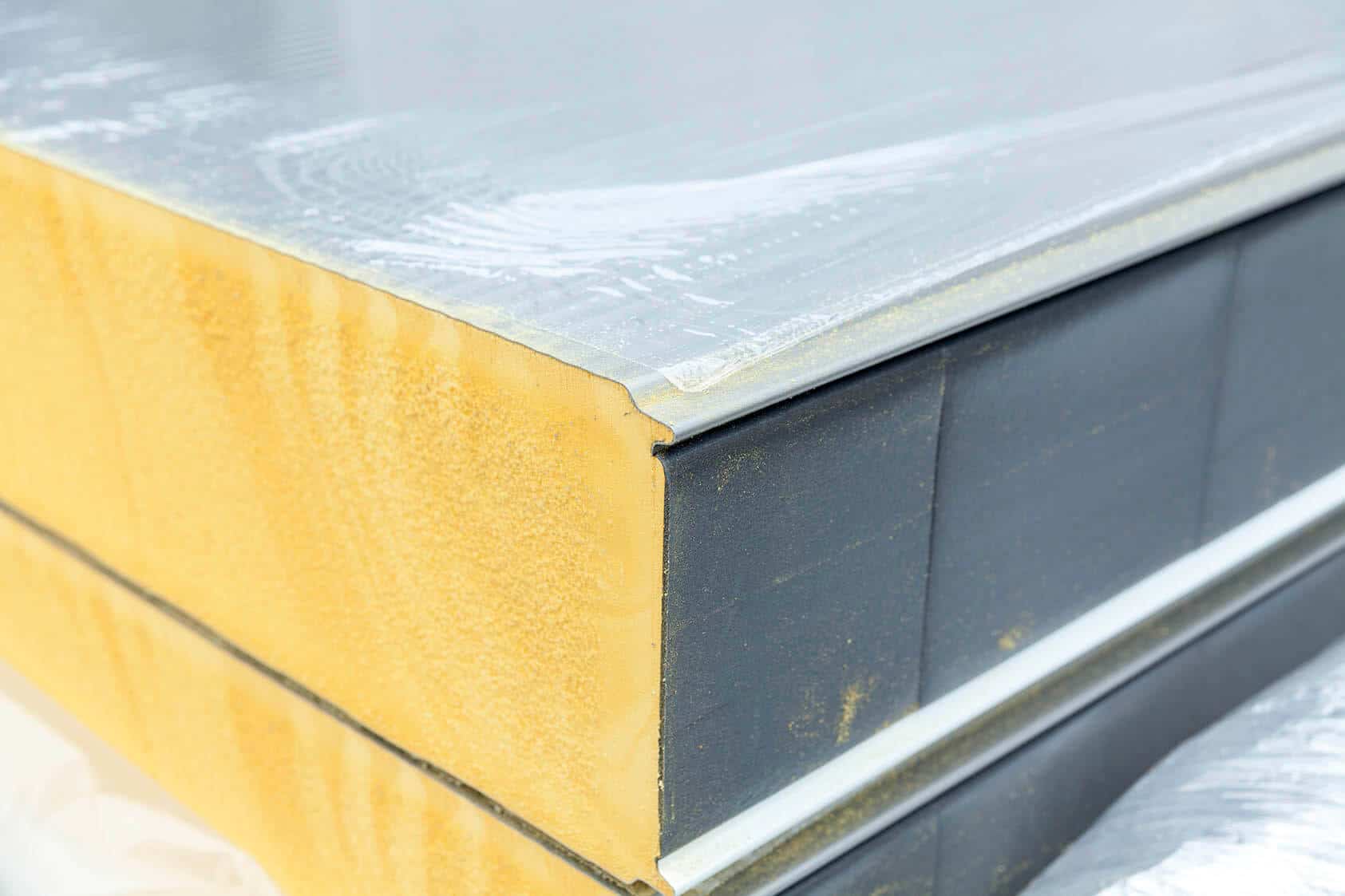

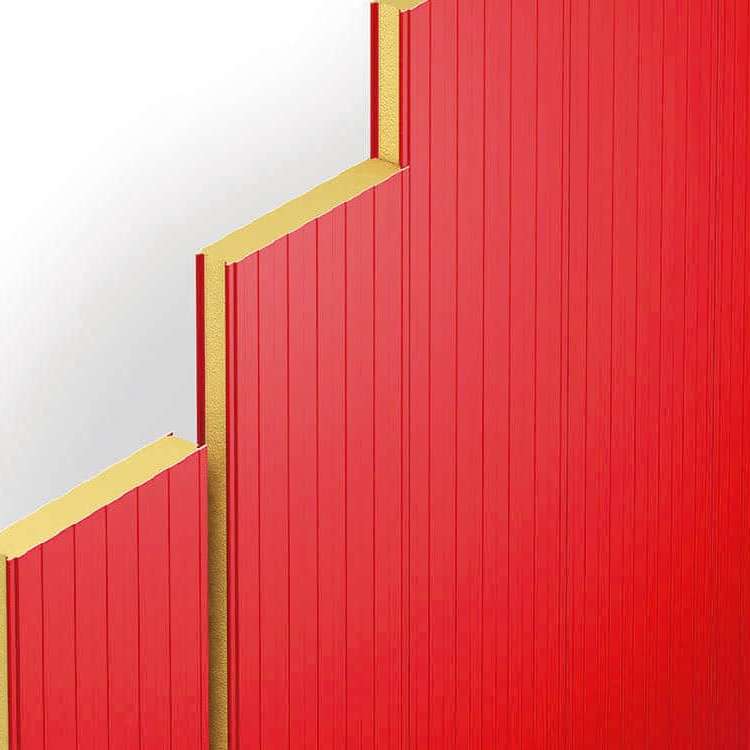

RIGID POLYURETHANE FOAM

In order to choose the optimal silicone surfactant for any specific polyurethane system, chemical and processing requirements have to be taken into account:

- Chemical requirements are given by the type of polyol, isocyanate and blowing agent used. Other compounds such as catalysts also play an important role.

- For processing requirements, points to consider include mixing efficiency, curing conditions and flow demands.

- Our selection guide shown in the table reviews the recommended products for any specific application, taking into account the blowing agent used, which plays a critical role in any formulation.

Additional products can be recommended, or adjusted to fulfil any specific requirement.

PU SHOE SOLES

Silicone surfactants are surface active additives that act as cellular regulators in PU shoe sole systems. Taking advantage of its emulsification properties, an improvement of the miscibility of the various liquid components is obtained, thus a better pigment distribution, less flow lines and a general improvement in various physical properties are some of the benefits achieved using this additives.

Cell openers are used in medium to low densities to reduce shrinkage and to improve the dimensional stability.

STANDARD FLEXIBLE SLABSTOCK POLYURETHANE FOAM

High active silicone surfactants for standard flexible slabstock foam. They improve the emulsification of the raw materials, providing the sufficient nucleation and stabilising the foam expansion.

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Coatings for the cheese industry

COATINGS FOR THE CHEESE SECTOR

Coating cheese, a technique used during the cheese making, plays an important role in packaging and appearance of the final product.

The cheese can be covered during various production process stages.

Before and during the ripening process

Regulation of moisture loss during the ripening process of the cheese and protection against unwanted growth of microorganisms such as molds and yeasts.

After the ripening process

Protection against microorganisms (molds and yeasts) and other contaminants. Protection against mechanical damage of the rind during transport and distribution. And specific final appearance is obtained, such as a particular colour.

THE VIPLAST RANGE

The use of our VIPLAST product range VIPLAST is a suitable way of cheese conditioning, improving the appearance of the piece during the ripening, storage and sale.

It is a surface treatment which offers the advantages of a protective external coating without migration into the cheese. The taste and the organoleptic properties of cheese are not affected in this way.

The following main features of our cheese coatings are of interest:

- Protection of the rind against microbial defects caused by molds and yeasts.

- Protection against mechanical damage of the rind during ripening (surface cracking) and transport.

- Reduction of excessive weight loss of the cheese (dehydration) without affecting the ripening process, decreasing moisture loss also means revenue loss in comparison with untreated cheese.

- Positive influence on the desired flavour, texture, consistency and appearance of the cheese is noted.

- Standardization of cheese quality.

Our VIPLAST range not only includes plastic coatings but also edible ones, based on food additives such as fatty acid esters, natural gums or celluloses.

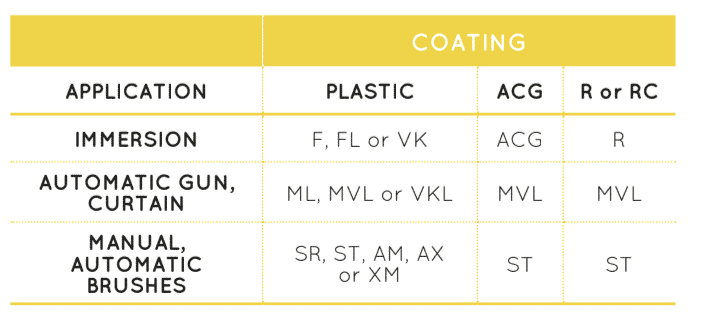

PLASTIC COATINGS

-

- The range of PLASTIC coatings is perfectly suited to needs such as the process of cutting and portioning cheese, the need for fast drying, adequate moisture resistance and vacuum packaging.

- They do not penetrate the product and they regulate the ripening process of the cheese without affecting the smell or the taste of the treated piece.

- The coating finish can be shiny, satin or matt.Cutting wedges (entrainment of particles) drying rate and moisture resistance (vacuum packing) can be adjusted in different formulations.

NATURAL COATINGS

- The range of NATURAL coatings is based on food additives (with code E according to EU Regulation No. 1333/2008). In this group ACG coatings, based on aqueous emulsions of E-472a (acetic acid esters of mono and diglycerides of fatty acids) are worth mentioning – and also R or RC coatings, which are formulated with gum(E-410-415) and/or cellulose (E-460-466) in aqueous solution. R or RC coatings, formulated with permitted preservatives for the external treatment of cheese, can be considered edible, together with coated cheese.

- Greater permeability than plastic coatings, speeding up the ripening process.

- Natural, handmade appearance.

- Easy elimination, making machinery and equipment easier to clean.

On customer request, the addition of preservatives blends to the VIPLAST range (based on natamycin, sorbates and other food additives) offers protection of the cheese against molds and yeasts.

Besides, there is an extensive catalogue of colours for painting the cheese, with a shiny, satin or matt finish.

Our VIPLAST coatings range can be adjusted to any system of coating application. The following table shows the nomenclature according to the application and the type of coating.

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Release agents for polyurethane foam

APPLICATIONS

CONCENTROL release agents have been developed after years of intense research with experience in sectors as diverse as:

- Car: seats, backrests, headrests, sunshades, steering wheels, dashboards, soundproofing, gear shift knobs, window encapsulation, armrests, air filters, etc.

- Footwear: single or dual density soles as such or in direct injection process.

- Furniture: padding for sofas and office chairs, mattresses, pillows, armrests, imitation wood pieces, etc.

- Construction: thermal and sound insulation panels, decorations, moldings, etc.

- Electrical applications

- Others: toys, navigation, aviation, sports equipment, etc.

MOLDED PIECES

Molded polyurethane parts are present in a wide variety of industries and applications, and their use is constantly expanding.

Applications can be classified according to the type of foam and type of process as follows:

- Hot cured flexible foam

- Cold cured flexible foam

- Integral skin flexible foam, rigid and semi-rigid

- Rigid foam, semi-rigid and R.I.M

- Elastomers

QUALITY COMMITMENT

Every day, more polyurethane molding companies trust in our products and in CONCENTROL as we fulfill the most demanding requirements:

- Quality Assurance guaranteed by the ISO 9001/2008 Certificate

- Effective and reliable products

- Security of supply thanks to an extensive stock

- Flexibility and agility in adapting products to production processes

- International and specialized technical and commercial service

- Special commitment to the research and development of new products

- Preservation of the environment supported by the ISO – 14001 certificate

PRODUCTS

CONCENTROL release agents provide a specific and efficient solution for all types of castings in polyurethane, including those whose needs are increasingly demanding regarding the appearance, surface coating, high productivity, cost, mold cleaning, easy application and protection of the working environment and the environment.

Our product range is extensive and constantly evolving, which keeps us at the forefront of the current challenges set by the industrial sector.

CONCENTROL can supply products to all sectors with traditional solvent based release agents, concentrates, concentrated for dilution, hybrids and water based. The following basic lines of products are available:

- Traditional solvent based products, low solids and aliphatic solvents flashpoint <21 ° C

- Concentrated solvent based flash point> 23 ° C and <55 ° C and >55°C

- Hybrid products 50:50 and 70:30 : The carrier consists of 50 parts of water and 50 of solvent (50:50) in the first case, and 70 of water and 30 of solvent (70:30) in the second case.

- 100 % water based or co-solvent ready to use products.

- Solvent based concentrates for dilution: High solids, low viscosity, easy to dilute and with high stability after dilution.

- 100% Water based concentrated for dilution.

A detailed analysis of working conditions of any production line allows our experts to suggest possibilities to implement each type of base products, and also advise on the procedure for applying them, which may be manual, by spray or robotic systems.

It is highly important to highlight our new generation of water-based products for automotive foams. We offer all kinds of finishing, from oily to dry, with low mold build up, and applicable for foams based on MDI and/or TDI.

Our mold release agents are complemented by a wide range of additives:

- Solvent or water based reinforcing pastes.

- Water based additives to treat demolded surfaces, providing anti- noise properties or sliding surface.

- Mold cleaners.

- One component water based contact adhesives, specially designed for repairing polyurethane foam molding processes, allowing sanding immediately after bonding, with no waiting time.

CONCENTROL is always ready to adjust new products to meet 100% of each customer’s requirements. Simply contact us and one of our specialists will visit you anywhere in the world to improve or adjust your product, developing new references if necessary.

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.