Wax emulsions

EMULTROL® and ORDISOL® wax and/or oil emulsions consist of a wide and versatile product range, which enables them to be included in many different sectors of application.

CHARACTERISTICS

Emulsions of different ionic character, formulated from a wide range of materials such as: polyethylene wax, paraffin, carnauba, montana, oils, fats etc.

MAIN SECTORS OF APPLICATION

They can be used in product formulations for floor treatments, wood finishes, car maintenance products, paper, paint and coatings, inks and varnishes, fiberglass, textiles, domestic use, lubricants, release agents etc.

PROPERTIES

EMULTROL® and ORDISOL® emulsions give properties such as smoothness, matte effect, improved shine, non-slip properties , scratch resistance, water repellence and in general, modification of the surface coating.

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Defoamers

INTRODUCTION

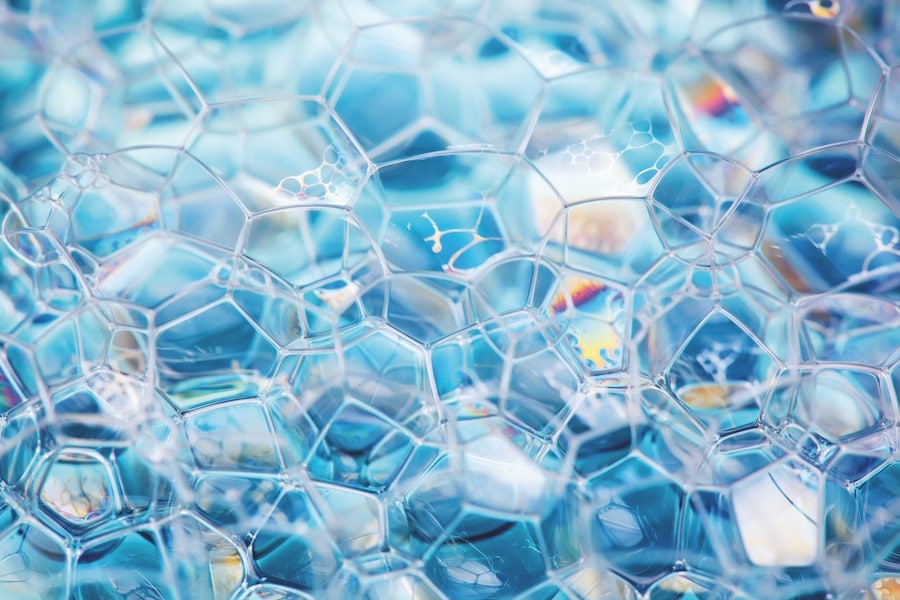

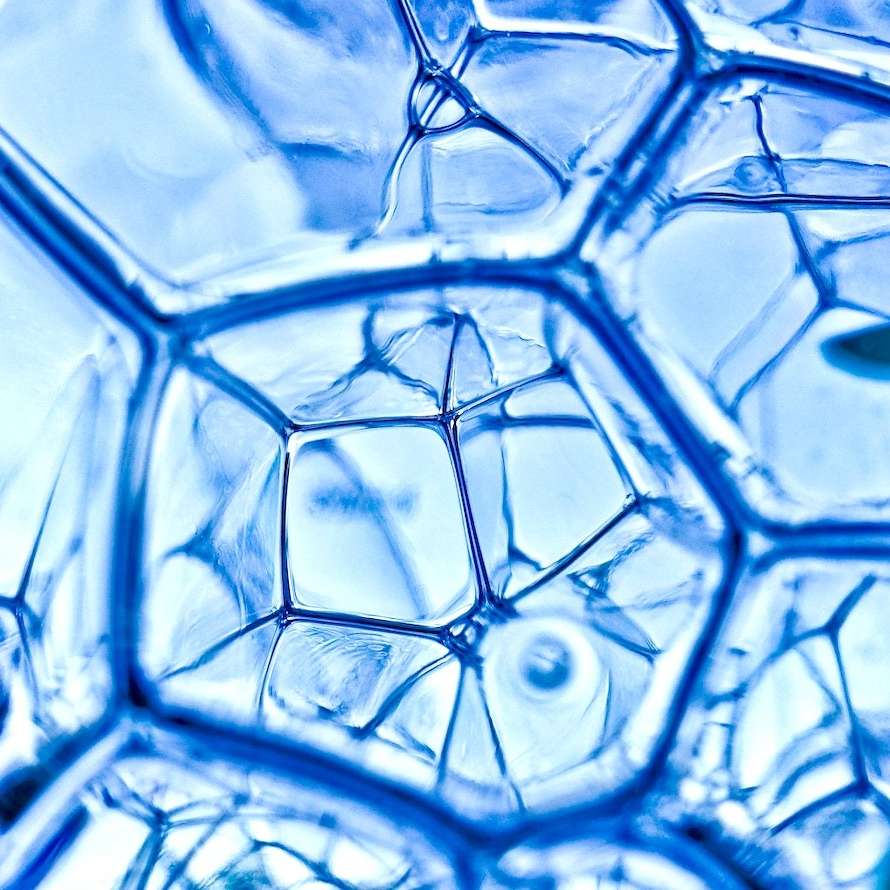

Foam is a dispersion of air and other gases in a liquid or solid. Apart from a few exceptions (foams in shampoos, shaving creams, hair styling mousses, carpet cleaners, polyurethane or other polymers that insulate homes) foams are generally undesirable. Foams disturb production sequences in which liquids, particularly water, have an important function as transporting media, and in the worst cases they can even bring such processes to a standstill. Furthermore, foams can lead to lower production yields and finished products of poorer quality.

HOW IS FOAM FORMED

We considered here those foams that are very stable, which in the most unfavourable cases may even dry without breaking down. These foams are generally only formed if the water contains surface-active agents (surfactants, wetting agents, emulsifiers). Foams that break down very quickly are not likely to cause problems and usually an antifoaming agent is not required.

HOW IS FOAM CONTROLLED?

We can control foam in two ways:

- DEFOAM (Destroy it)

- ANTIFOAM (Prevent it)

Defoamers are products that destroy foam that has already formed. Usually defoamers don’t prevent foam from forming.

Antifoams are products that prevent the formation of foam.

To better understand the difference, it is important to notice at what point in the process they are used.

HOW DO ANTIFOAMS WORK

Most antifoams work introducing defects into the foam lamella. Fine hydrophobic solid particles contained in the antifoaming agent formulation (waxes, paraffins and silicas) help the foam bubble to burst, so that the entrapped air escapes.

WHICH ARE THE MAIN CHARACTERISTICS OF ANTIFOAMS

Silicone antifoams are efficient (effective dosages lower than 50-100 ppm active silicone), long lasting, they act as antifoams and defoamers, are safe (many comply with FDA and European Regulations) and have low surface tension for the effective foam control of different foaming media.

Oil antifoams are used in applications where silicone is not recommended. Effective foam control in paints, coatings, detergents and adhesives.

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.

Silicone emulsions

INTRODUCTION

Silicone emulsions typically contain a silicone component (usually a silicone oil), water and the required emulsifiers to obtain a stable emulsion. From the chemistry perspective, a silicone component is a finite chain of silicone and oxygen atoms bonded one to each other. Besides of these bonds, silicone itself has two other bonds to organic groups. In most cases, these components are methyl groups (CH3) that provide to the silicone component its characteristic semi-organic behaviour.

MACRO & MICRO EMULSIONS

Silicone emulsions are commonly grouped into two types based on particle size.

SILICONE MACROEMULSIONS

- White appearance, stable emulsions with different % of silicone content

- Typical average particle size = 0.1 to 1 micron

- They can contain up to 60% silicone content

- They can be formulated using silicone oil with different viscosities, being the most common 350cps and 1000 cps

- Once applied, when water has been evaporated, the silicone remains on external surfaces, where they offer benefits like the reduction of the dynamic coefficient of friction, providing a lubricating effect

SILICONE MICROEMULSIONS

- Translucent appearance, very stable in extreme conditions.

- Very small average particle size (< 0,4 micron)

- The silicone oil is usually a very high viscosity type (>100000 cps)

ADVANTAGES

- Good thermal and dilution stability

- Compatible with anionic and non-ionic soaps/surfactants. Easy application, non-yellowing after time

- Good surface wetting characteristics

- High gloss and colour intensity

- Good slip and abrasion characteristics

- Provides natural handle to fabric

- Can be used as a thread lubricant to reduce needle temperature, and wear and thread breakage

NEWSLETTER

Subscribe to receive information about the latest studies conducted in our laboratories and the latest news from our catalogue.