At Concentrol we innovate with chemistry to have a positive impact on society and the planet. One of our key areas of expertise is the cheese industry. Through our Food Processing Aids product line, we draw upon our extensive experience in developing chemical solutions for the food sector. Our offerings include surface treatments for cheeses, ensuring ideal packaging and transportation, along with auxiliary products for food safety and hygiene.

In the following article, we will delve into the selection of preservatives for cheese coatings, the relevant regulatory framework, and other crucial considerations.

A significant challenge within the food industry, especially in cheese production, is the unwanted growth of molds and yeasts.

Cheeses undergo a curing process, that is, maturation over time. During this process, various microorganisms from the environment and cheese surface can proliferate, potentially affecting and colonizing parts or even the entire surface of the cheese.

In Europe and America, food regulations dictate which preservatives are permitted and establish usage limits. Unauthorized preservatives or active ingredients must undergo evaluation and approval by food authorities before use.

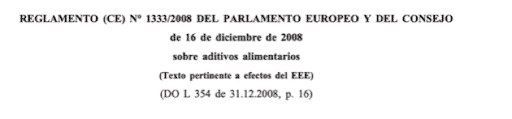

EU Regulation No. 1333/2008 is the reference framework in the European Union on food additives and their uses:

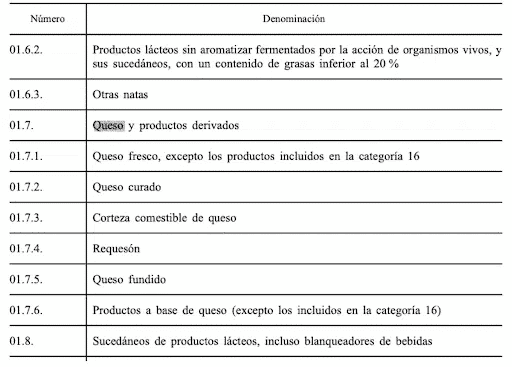

Among the different foods detailed in the regulations, cheeses and their subcategories are detailed in point 01.7.

Cured cheeses are included in section 01.7.2

Additives allowed in cured cheeses are found in the detailed table below:

| E number | Name | Max dose (mg/l or mg/kg) | Notes | Restrictions or exceptions |

| E 1105 | Lysozyme | Quantum satis | ||

| E 120 | Cochineal, Carminic acid, Carmines | 125 | (83) | only reddish marbled cheese and cheese with red pesto |

| E 140 | Chlorophylls and Chlorophyllins | Quantum Satis | only sage derby cheese | |

| E 141 |

Cupric Complexes of Chlorophylls and Chlorophyllins |

Quantum satis | only sage derby cheese, cheese with green or red pesto, cheese with wasabi and green marbled cheese with herbs | |

| E 153 | Charcoal | Quantum satis | only Morbier cheese | |

| E 160a | Carotenes | Quantum satis | only orange, yellow and off-white aged cheese |

| E number | Name | Max dose (mg/l or mg/kg) | Notes | Restrictions or exceptions |

| E 160b | Annato, Bixin, Norbixin | 15 | only aged orange, yellow and off-white cheese and cheese with red or green pesto | |

| E 160b (ii) | Annato, Bixin, Norbixin | 50 | only Red Leicester cheese | |

| E 160b (i) | Annato, Bixin, Norbixin | 35 | only Mimolette cheese | |

| E 160c | Paprika extract, Capsanthin, Capsorubin | Quantum satis | only aged orange, yellow and off-white cheese and cheese with red pesto | |

| E 163 | Anthocyanins | Quantum satis | only reddish marbled cheese | |

| E 170 | Calcium carbonate | Quantum satis | ||

| E 200-202 | Sorbic acid and Potassium sorbate | 1000 | 1 2 | only sliced cheese, cut and packed; layered cheese and cheese with added foods |

| E 200-202 | Sorbic acid and Potassium sorbate | Quantum satis | only surface treatment of cured products | |

| E 234 | Nisin | 12.5 | 29 | |

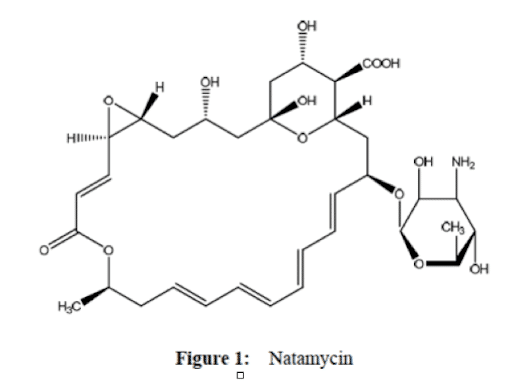

| E 235 | Natamycin | 1 mg/dm2 of surface (not present at 5mm depth) | only surface treatment of uncut hard, semi-hard and semi-soft | |

| E 239 | Hexamethylenetetramine | 25mg/kg residue amount as formaldehyde | only provolone cheese | |

| E 251-252 | Nitrates | 150 | 30 | only hard, semi-hard and semi-soft cheese |

| E number | Name | Max dose (mg/l or mg/kg) | Notes | Restrictions or exceptions |

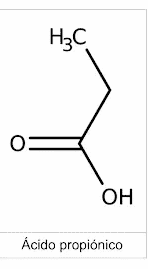

| E 280-283 | Propionic acid and Propionates | Quantum satis | only surface treatment | |

| E 460 | Cellulose powder | Quantum satis | only aged cheese sliced and grated | |

| E 500 (ii) | Sodium acid carbonate | Quantum satis | only sour milk cheese | |

| E 504 | Magnesium carbonates | Quantum satis | ||

| E 509 | Calcium chloride | Quantum satis | ||

| E 551-559 | Silicon dioxide and Silicates | 10,000 | only sliced or grated hard and semi-hard cheese Period of application: until January 31, 2014 |

|

| E 551-553 | Silicon dioxide and silicates | 10,000 | only sliced or grated hard and semi-hard cheese Period of application: as of February 1, 2014 |

|

| E 575 | Glucono-delta-lactone | Quantum satis | ||

| (1) Additives may be added alone or in combination (2) The maximum dose is applied to the sum and the doses are expressed as free acid. (29) This substance can be present naturally in some cheeses as a result of fermentation processes. (30) In cheese milk, or equivalent dose if added after removing whey and adding water. (83). Maximum aluminium limit from all the aluminium lacquers of E 120 cochineal, carminic acid, and carmines: 3.2 mg/kg. No other aluminium lacquers can be used . For the purposes of article 22, section 1, letter g), of Regulation (EC) No 1333/2008, this limit must be applied from February 1, 2013 onwards. |

||||

The edible cheese rind section is included in food category 0.1.7.3

From the list in the table above, the only preservatives currently allowed are natamycin (E-235), sorbates (E-200, E-202), and propionates (E-280, E-281, E-282). Natamycin is the most used preservative, since it has no effect against bacteria and is very effective against most types of mold and yeast.

Propionates are used in combination with natamycin in some cases because they have very low efficacies on their own.

Recent studies have revealed that natamycin’s limited solubility in water, approximately 40 ppm, is the key determinant of its effectiveness as a preservative. Natamycin only exerts its preservative action when it is in its soluble phase, so concentrations exceeding 40 ppm hardly improve its efficacy.

As an alternative to the aforementioned preservatives, investigations have explored the use of other food additives, including lactic acid and acetic acid. While these additives exhibit some preservative capabilities, their effectiveness in the context of cheese is limited and remains unproven, even when used in combination with traditional preservatives.

Selecting the right preservatives to prevent the growth of molds and other microorganisms is a complex undertaking.

At Concentrol, we are committed to developing various coating solutions tailored to the specific requirements of each cheese product. Our company places great emphasis on continuous research, a cornerstone of our operation, led by our Research and Development department. This enables us to design innovative solutions and address potential challenges in the cheese manufacturing process.