Concentrol’s Food Processing Aids Division has a mission to offer chemical solutions for the preservation, protection, processing and finishing of food products. Precisely, one of the sectors in which Concentrol works the most is cheese. We make essential coatings in its manufacture, a fact that gives us added value worldwide in the cheese sector.

Cheese making: basic concepts

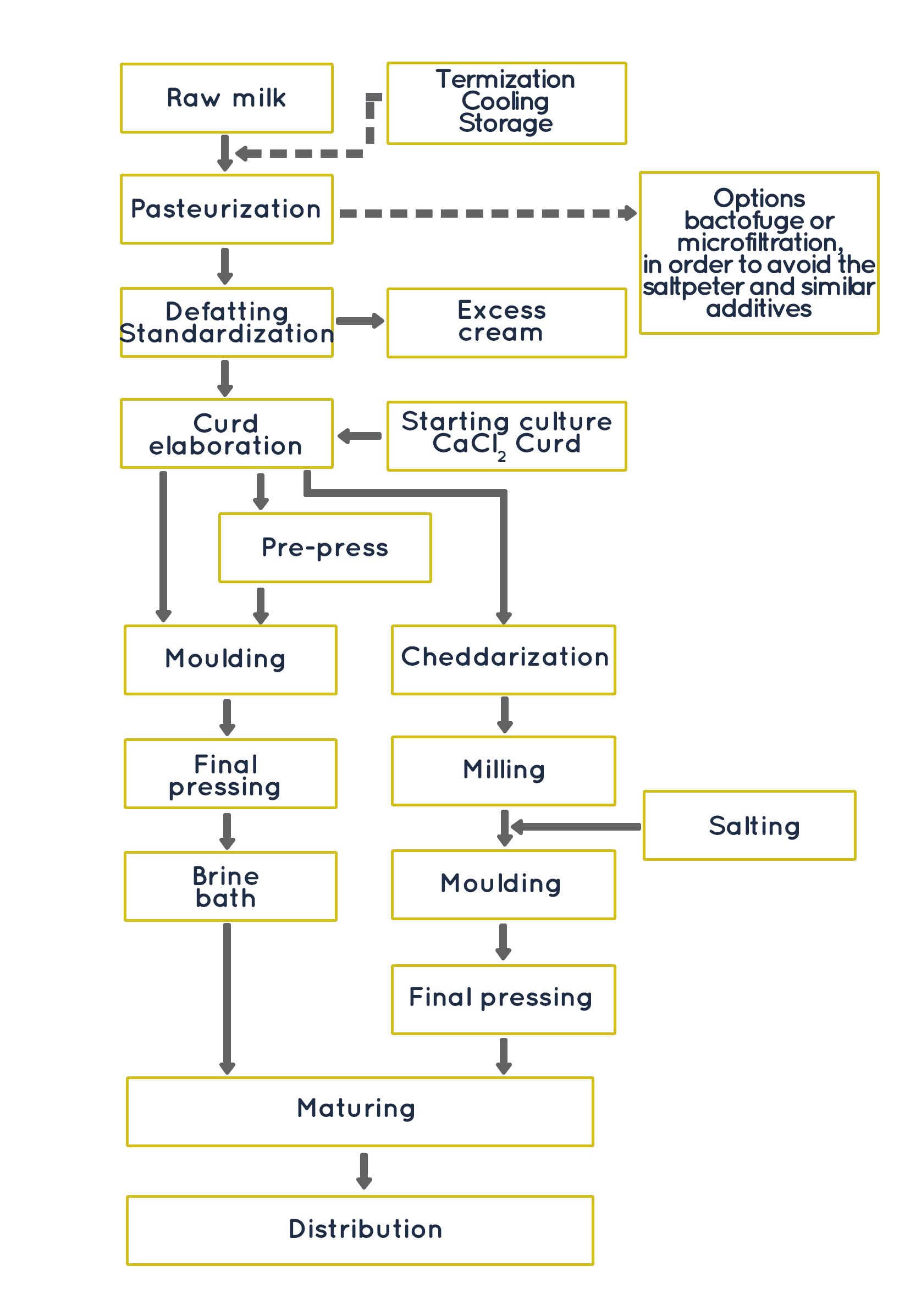

Cheese is a food that is obtained by maturing milk curd, once the whey has been removed in a pressing process. Cheese manufacturing consists of different stages, being the maturation phase where Concentrol can contribute its knowledge, proposals and products:

1. The first step in cheese making is based on the treatment of milk, which in turn consists of different stages:

1.1. Receiving milk as raw material.

1.1.1.- Sanitization of milk separating possible solid particles such as impurities.

1.1.2.- Homogenization with centrifuges or similar to guarantee specific fat parameters. The absence of this process would lead to manufacturing with milk called “whole”.

1.1.3.- Cooling of the milk to 3-4 degrees for its preservation.

1.1.4.- Thermal treatments of milk. Pasteurization, bringing the milk to about 70-80 degrees, for 15 to 40 seconds to eliminate pathogenic microbes. Not performing this operation means working with raw milk (*). Subsequently return the milk to storage temperatures.

(*) Using raw milk is recommended for long-aged cheeses (over 60 days) since the process generally eliminates pathogenic microorganisms, and it keeps those that give the cheese character and are safe for consumption from a health point of view.

1.2. Filling vats with pasteurized or raw milk, and coagulation.

1.2.1.- Increasing the temperature in the vat to about 25-30 degrees and adding milk bacteria and ferments that will transform into flavours and aromas that develop during maturation.

1.2.2.- Coagulation by addition of rennet. Next, rennet is added, which transforms milk into cheese, as casein (the main protein in milk) coagulates, concentrating much of the milk fat and other solid components. There is animal rennet (from the stomachs of ruminants), microbial and vegetable (from some plants such as thistle flower).

1.2.3.- Coagulation by acidification of milk. If the temperature is allowed to drop, the acidity of the medium rises until soured milk is created. Enzymes, acidification of the medium (lactic acid), natural rennet (chymosin-animal pepsin), microbial rennet (proteolytic enzymes produced by microorganisms) or vegetable rennet (thistle flower) are used in this process. All of them have the mission of coagulating the casein in milk.

1.3. Cutting.

Once the milk has curdled, cuts are made using blades or rakes. There will be more or less cutting depending on the amount of whey to be removed (the more cutting, the more whey). Leftover whey is removed.

1.4. Heating.

The cut and drained paste is heated to temperatures of between 30 and 50 degrees, constantly stirring it so that the grains created in the cut do not rejoin. The higher the temperature, the more whey will be created again.

1.5. Pressing.

After heating, molds are filled and subsequently pressurized, or not, for the final elimination of more whey that allows the adaptation to mold shapes. Depending on the pressure exerted we refer to cheeses made of pressed paste or not. At this point, if the rennet arrives with a lot of whey, the grains melt into each other homogeneously. If the rennet gets “drier”, the cheese cutting will provide some holes (which will be the beginning of their creation due to the development of carbonic gasifying agents inside when trying to release the air, detectable in some Manchego cheese, generally considered “pressed paste”, as well as in Emmental or Gruyére type cheeses, of “non-pressed” paste. In the latter these holes are also formed due to the presence of added lactic bacteria to cause this effect.

2. Next, the brine bath. Once the cheese leaves the press and is already removed from the mold, it is placed in a bath of water and salt for a certain time. The salt concentration and the immersion time depend on what type of cheese we want to obtain.

3. Third, the draining of the brine water. After the necessary time has elapsed in the brine bath, the cheese is removed from the bath and the drying process begins. Previously, the excess brine (salted water) that the cheese has absorbed must have already been removed. For this, there are two methods:

- Airing of the cheese. It is the traditional method. Consisting of leaving the cheese on racks that allow the brine to exude. This process normally takes place in 1 to 3 days from the moment the cheese has been removed from the brine. During this procedure, the turning of the cheese facilitates the drying and the exudation of most of the brine.

- Air blowers. It is the default industrial method. It replaces the aeration process in industrial facilities to benefit the optimization of manufacturing time. As it comes out of the brine, the cheese passes under dry air blowers, which remove a substantial part of the brine, especially the amount on the surface. The brine that is not eliminated (the one that is inside the cheese) will do so gradually during the drying process, after the cheese is coated.

4. The next step in the cheese manufacturing chain is the treatment with a protective coating. To prevent unwanted mold and yeast growth and also minimize cheese water loss (weight loss), protective outer coatings are applied to the cheese. There are different types of coatings (plastics, rubber or cellulose based, or based on other film-forming agents), which are applied in different ways (application by immersion bath, application by spray painting, application with a brush machine or manual application).

- Application of coating by immersion or semi-immersion. It consists of a bath of a certain volume or a bath with a covering curtain that falls on top of the cheeses that are floating. This type of application is used mostly for the initial treatment of cheese after leaving the brine. The coating used is of low viscosity, with a low dry extract and a high amount of preservatives.

- Application in painting booth (spray). It is a treatment with an intermediate viscosity coating and a high percentage of dry extract, in order to promote rapid drying. Normally, the cheese, once treated, is subjected to drying by means of hot and dry air tunnels.

There is different industrial equipment for this type of application, which is generally used in the final treatment of cheese, after the maturing process. In many cases, this final treatment is with a coloured paint that also contains preservatives.

- Application by brush machine. It is based on the treatment of the coating, with automatic equipment consisting of brushes impregnated with coating, so that they automatically cover the surface of the cheese. These treatments are generally used in cheeses without a strap, that is, a smooth rind, since they are usually applied consecutively throughout the maturation process. Therefore, it is common to apply 5 to 15 layers of coating depending on the maturation time. The coatings used are of intermediate viscosity (about 3000-5000 cps) and high dry extract to promote drying of the paint once applied. Because many coats are applied, the amount of preservatives used is low. In many cases, these coatings have coloration, the most common shade being orange-yellow.

- Manual application of the coating. In small cheese factories and in the treatment of small amounts of cheese, manual treatments consisting of sponges or brushes are used to externally coat the cheese. The coatings used are of high viscosity (> 10000cps) and high dry matter, and can be colourless or coloured. The amounts of preservatives are variable depending on the number of treatments that the cheese undergoes in its maturation process.

5. Once the coating is applied, the flavour, smell and texture of a cheese depend on the maturing and curing process. This phase consists of slow drying of the cheese with controlled loss of water, where the cheese evolves in different stages. An example can be found in the curing found in Spain and which, in summary, consist of 4 stages:

- Fresh cheese (<5 days)

- Young cheese (between 5 and 30 days)

- Semi cheese (between 30 days and 60 days)

- Cured, hard or aged cheese (> 60 days)

There are many other options depending on the type of cheese, its size and the country where it is manufactured. One of the most important characteristics to control during the cheese maturing process is the temperature and humidity of the curing chambers. Air circulation also plays a very important role, since it has a notable incidence in the growth of molds and yeasts. A homogeneous maturation of the cheese is achieved with successive turning and with a covering of coatings, to allow a slower and more controlled evaporation of the water during the cheese curing process.

During this curing process, mold growth phenomena naturally occur if no preservative coatings are used. Although totally preventing mold growth is a complicated task – the preservatives allowed by food regulations are limited – in most dairies they try to prevent their proliferation. This challenge is the main demand of the cheese sector and Concentrol’s research work has been developed upon it.

6. Lastly, the final painting. Before the cheese is marketed, in many cases a final coloured coating is applied to it. This last treatment aims to prevent the growth of molds and yeasts once the cheese has been sold. In addition, this coloured coating offers a distinctive finish by each manufacturer and avoids problems due to friction and knocks on the cheese rind.

Currently, cheese is sold either vacuum-packed or in a protective atmosphere system, in order to minimize the possible growth of mold. However, there is a significant percentage of cheese that is sold packed in cardboard boxes. It is precisely in the latter case that the final application of a paint containing preservatives becomes more important.

At Concentrol we bet day by day on the research of new chemical solutions that cover the needs of the population. This time, we want to show the work of our experts when making cheese-coating solutions, through four studies carried out by Concentrol. Soon we will discuss the types of coatings and preservatives used.