At Concentrol we are constantly engaged in research and development of solutions. One of the sectors with which we work the most is cheese. Through the Food Processing Aids Division, we make products for the preservation and coating of cheeses.

There is a wide variety of coatings on the market for the external treatment of cheeses. They can be classified in different ways, one of them is depending on the type of application:

1.- Coatings designed to be applied as a protective treatment against the unwanted growth of mold on the surface. These are coatings that are usually colourless and are applied in the first treatment of the cheese and generally contain a greater amount of preservatives compared to those used in subsequent treatments. For example, amounts of natamycin between 500ppm and up to 3000ppm, and in some cases, other preservatives such as sorbates and propionates are used to achieve optimum effectiveness in anti-mold treatment.

2.- Coatings designed for a secondary anti-mold treatment that is applied during the curing process. They are applied to cheese that has already received some initial anti-mold treatment to ensure effective and lasting protection throughout the maturation process. For this reason, in most cases they contain preservatives such as natamycin, although in generally lower quantities than the first treatment. A usual amount of natamycin in these treatments is between 500ppm and 1000ppm, and in some cases with other preservatives such as sorbates and propionates.

3.- Coatings designed for a final treatment, before the cheese is sold. They are usually coloured.

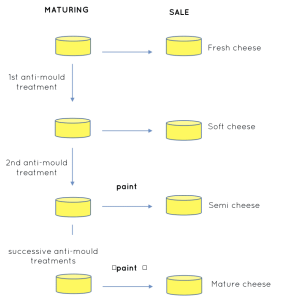

Also, there are different application schemes depending on the type of cheese and country.

- Scheme A (usual in Spanish cheese)

The first treatment is applied at the beginning of the maturation process. A second and even a third treatment is used in those cases in which the maturation of the cheese is very long. Normally, this process lasts up to a few weeks between treatments and always before the last final coloured treatment. The cheese can be put on sale at any time, depending on the desired maturation.

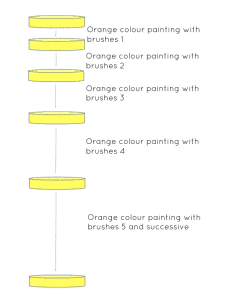

- Scheme B (usual in Dutch cheese)

In this case, coating treatments are applied very consecutively over time, normally with coloured coatings. By applying coatings very often, you can work with a lesser amount of preservative. The cheese can be sold at any time, depending on the desired curation.

Furthermore, depending on the chosen application form, the coatings have different physicochemical characteristics. Therefore, we must pay attention to the way in which the coating is applied by the client, and choose the most appropriate for each case.

The coatings that are applied by immersion have the following physicochemical characteristics:

- Dry extract: 30%

- Viscosity: 100-150 cps

- pH: 4.5-6.5

- Colour: colourless

Coatings that are applied by spray pistol have the following physicochemical characteristics:

- Dry extract: 35-40%

- Viscosity: 300-600 cps

- pH: 4.5-6.5

- Colour: Normally coloured, some colourless

The coatings that are applied with a brush machine (Dutch treatments) have the following physicochemical characteristics:

- Dry extract: 40%

- Viscosity: 3000-6000 cps

- pH: 4.5-6.5

- Colour: coloured, orange

The coatings that are applied manually have the following physicochemical characteristics:

- Dry extract: 40-45%

- Viscosity: 8000-15000 cps

- pH: 4.5-6.5

- Colour: colourless or coloured

At Concentrol we work to develop solutions that best suit the needs of our customers. Coatings are of vital importance for the external treatment of cheeses. This time, we have seen the types of coatings that exist according to their form of application. Coming soon, we will talk about preservatives in coatings and microbiological tests of coatings carried out in Concentrol.